Introduction

Selecting the right caster for your equipment may seem like a minor decision, but it can greatly affect the performance of your machinery, carts, or furniture. The two primary types of casters—fixed and swivel—are designed for distinct purposes and specific movements. Choosing incorrectly can lead to inefficiency, challenging maneuverability, and increased maintenance costs. In this article, we’ll outline the key differences between fixed and swivel casters, examine their pros and cons, and guide you in determining the best option for your specific needs, whether you’re operating in an industrial environment, managing a retail space, or upgrading home furniture.

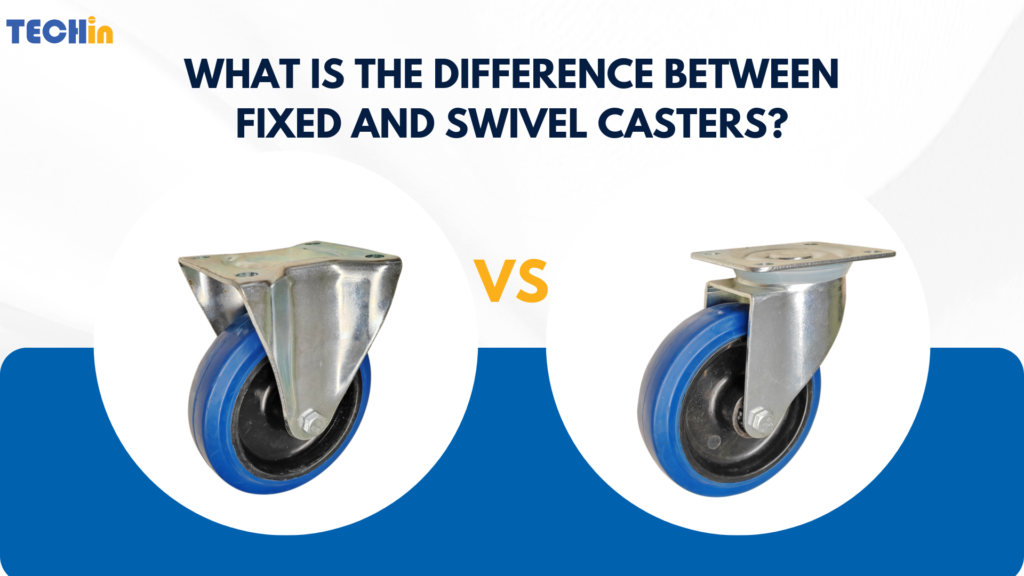

Fixed casters offer stability and can support heavier loads but are restricted to straight-line movement. In contrast, swivel casters provide flexibility with their 360° rotation, making them perfect for navigating tight spaces and corners. The optimal choice hinges on your specific requirements: whether you prioritize handling heavy loads or need smooth, effortless maneuverability in confined areas.

With that overview in mind, let’s delve deeper into the specifics of fixed and swivel casters—examining how they function, identifying their ideal applications, and highlighting the factors you should consider when deciding between the two.

What Are Fixed Casters?

Fixed casters, often referred to as rigid casters, are designed to roll in a straight line. This means they do not rotate or swivel, making them ideal for applications where directional movement is needed, particularly in wide, open spaces where consistent linear motion is important.

Key Features:

- Directional Stability: Fixed casters excel in moving loads in a straight line. Because the wheels cannot pivot or swivel, they remain aligned, providing stability even under heavy loads.

- Simple Design: Without the need for a swivel mechanism, fixed casters have fewer parts, which translates to less wear and tear. This makes them ideal for long-term, low-maintenance use.

- Heavy Load Capacity: The fixed nature of the caster allows for a greater distribution of weight, making these casters more suited to carrying heavy loads. They are often built with robust materials such as steel or industrial-grade polymers.

Ideal Applications:

- Warehouses and Industrial Settings: Fixed casters are a staple in environments like warehouses where stability is crucial, particularly when transporting heavy goods in straight lines down long aisles. The lack of swivel prevents accidental lateral movement, which is important for safety in busy industrial spaces.

- Large Transport Trolleys: Heavy-duty carts, especially those used in environments like manufacturing plants or logistics centers, benefit from the load capacity and stability offered by fixed casters.

- Storage Racks: In fixed locations where items need to be wheeled forward and backward but do not require turning, fixed casters ensure a secure and stable platform.

What Are Swivel Casters?

Swivel casters are designed to provide maximum maneuverability by allowing the wheel to rotate 360 degrees. This full range of motion enables users to push, pull, and turn carts or furniture with ease, even in confined or crowded areas. The casters rotate around a pivot mechanism, typically with ball bearings, which helps the wheel move smoothly in any direction.

Key Features:

- 360° Movement: The primary advantage of swivel casters is their ability to rotate fully, making them ideal for navigating tight spaces, sharp turns, and complex environments. Unlike fixed casters, these can be pushed from any angle, offering far greater flexibility.

- Ball Bearings for Smooth Turns: Many swivel casters feature ball bearings in the pivot joint, which allows for smoother and quicker turns. This is especially important when handling heavy loads that require controlled movement.

- Wide Range of Applications: Due to their flexibility, swivel casters are widely used in environments where mobility is key, such as retail stores, hospitals, and offices.

Ideal Applications:

- Retail and Home Use: Swivel casters are commonly found on shopping carts, office chairs, and mobile shelving units. They allow users to easily navigate narrow aisles, make quick direction changes, and avoid obstacles with minimal effort.

- Medical Equipment: In hospitals, maneuverability is critical, and swivel casters allow medical professionals to move beds, equipment carts, and even wheelchairs quickly and safely through crowded spaces.

- Food Service Carts: In busy kitchens or catering events, swivel casters make it easy to move heavy food carts smoothly, even in tight or cluttered spaces.

Advantages and Disadvantages of Fixed Casters

Advantages:

- Stability in Movement: Fixed casters are incredibly stable when moving in a straight line, which makes them ideal for transporting heavy loads across long, straight distances. The lack of sideways movement prevents items from wobbling or tipping over.

- Durability: With fewer parts, fixed casters are more durable and less prone to wear. This is especially important in industrial settings where casters must withstand long hours of use with minimal downtime for repairs.

- Higher Load-Bearing Capacity: Fixed casters are better suited for applications that require transporting heavy loads. Their design supports weight more evenly, allowing them to carry significantly more weight than most swivel casters.

Disadvantages:

- Lack of Maneuverability: The inability to turn limits the use of fixed casters in environments where flexibility is required. In spaces with tight corners or complex pathways, fixed casters can become cumbersome, requiring more physical effort to lift and turn equipment manually.

Advantages and Disadvantages of Swivel Casters

Advantages:

- Excellent Maneuverability: Swivel casters are unmatched when it comes to making tight turns and navigating complex environments. Their ability to rotate 360 degrees makes them perfect for areas where space is limited and frequent directional changes are required.

- Versatile Use: These casters offer greater flexibility and can adapt to various environments, from offices and homes to hospitals and retail spaces. The ease with which they can move in any direction makes them a go-to option for many industries.

Disadvantages:

- Less Stability: While swivel casters offer more flexibility, they can lack the stability of fixed casters, especially when moving in straight lines or under heavy loads. Swivel casters may also be prone to veering off course, requiring more attention from the user to maintain direction.

- More Maintenance: Due to the complexity of their design—especially with ball bearings and pivot mechanisms—swivel casters tend to require more frequent maintenance. Dirt, grime, and general wear can affect their performance, causing them to swivel less smoothly or even jam over time.

How to Choose Between Fixed and Swivel Casters

The decision between fixed and swivel casters hinges on your specific operational needs. Here are some factors to consider when making your choice:

- Movement Needs: If your equipment or carts will be moving in straight, predictable lines (such as in warehouse aisles), fixed casters are your best bet. However, if you need to make frequent turns or navigate tight spaces, swivel casters offer the flexibility you need.

- Load Capacity: For heavy-duty applications, fixed casters are generally better as they can bear more weight. If load capacity is a critical factor in your decision-making process, fixed casters are more likely to meet your requirements.

- Space Constraints: Swivel casters excel in environments where space is tight or where you need to maneuver around corners. Retail environments, offices, and medical facilities often rely on swivel casters for their flexibility.

Can You Use Both Fixed and Swivel Casters Together?

Yes! Many applications benefit from a combination of both fixed and swivel casters. This is often seen in large equipment or carts, where two fixed casters are placed on one side (usually the back), and two swivel casters are positioned on the opposite side (the front).

- Enhanced Control: The fixed casters provide the stability and direction control needed for straight-line movement, while the swivel casters allow for easy turning and maneuverability when needed. This combination helps avoid the limitations of each type and gives you the best of both worlds.

- Improved Handling: Combining both types of casters makes it easier to control large equipment and navigate in different environments, balancing the benefits of stability and flexibility.

Common Uses for Fixed and Swivel Casters

- Fixed Casters:

- Warehouse carts

- Industrial trolleys

- Heavy machinery that moves in straight lines

2. Swivel Casters:

- Office chairs

- Medical equipment (hospital beds, IV stands)

- Shopping carts

- Food service trolleys

Conclusion

Choosing between fixed and swivel casters hinges on your unique situation and specific needs. Fixed casters deliver excellent stability, durability, and load-bearing capacity, making them ideal for industrial settings that demand straight-line movement. Conversely, swivel casters provide exceptional flexibility, perfect for maneuvering through tight spaces and complex environments. For many applications, particularly where both straight-line stability and maneuverability are essential, a combination of both caster types can offer the optimal solution. By thoroughly assessing your load, environment, and movement requirements, you can confidently select the right caster for the task.