Furniture Casters Manufacturer

Are You Looking For Furniture Casters?

Techin is a premier manufacturer of furniture casters, offering a wide range of products including Nylon casters, PP casters, Office chair casters, twin wheel casters, and stem ball casters. Our caster factory in China adheres to ISO, Reach, PAHs, RoHS and other EN standards, ensuring high-quality products that meet customer-specific requirements. Our products have been sold worldwide for a variety of applications in furniture, office equipment, medical devices, and retail displays.

Let's Talk About Your Caster Needs

The Ultimate Guide Of Furniture Casters

What Are Furniture Casters?

Furniture casters are essential components that allow furniture to move effortlessly across various surfaces. They reduce the effort required to relocate furniture and help prevent damage to flooring. Casters are available in different materials, sizes, and load capacities to suit diverse applications. The right caster can enhance the functionality and lifespan of furniture, making it more versatile and user-friendly.

The following section discusses everything you need to know about furniture casters. Included in this article are the different caster functions and the general caster parts. This article also discusses the commonly used casters in furniture applications.

Types of Furniture Casters and Their Functions

Furniture casters perform multiple functions within their application environment. To summarize, there are several key functions of furniture casters:

- Mobility: Allowing furniture to be easily moved from one location to another.

- Stability: Providing a stable and secure foundation to prevent tipping or accidental movement.

- Flexibility: Enabling furniture to pivot and turn smoothly.

- Support: Bearing the weight of the furniture and any additional load.

Each type of caster has specific advantages and is suited for particular applications. Understanding the unique functions of different casters can help in selecting the right one for your needs.

| Type of Caster | Mobility | Stability | Flexibility | Support |

|---|---|---|---|---|

| Fixed Casters | ✓ | ✓ | ✓ | |

| Swivel Casters | ✓ | ✓ | ✓ | ✓ |

| Brake Casters | ✓ | ✓ | ✓ |

Fixed Casters

Fixed casters provide stability and controlled movement, making them perfect for furniture that requires straight-line movement. They are often used in conjunction with swivel casters to provide a combination of mobility and stability. Common applications include storage racks and heavy machinery.

Swivel Casters

Swivel casters provide excellent mobility and flexibility, making them ideal for furniture that needs to move frequently and navigate tight spaces. They are commonly used in office chairs, rolling tables, and portable equipment.

Brake Casters

Brake casters ensure safety and stability by preventing the wheels from rolling or swiveling. They are essential for furniture that needs to stay securely in place when not in use. Brake casters are commonly used in medical equipment, retail displays, and workstations.

Furniture Caster Parts and Components

Furniture casters consist of several smaller parts. While specific caster types contain certain components definitive to that design, all furniture casters share major components. This section will discuss the different caster parts.

- Wheel: The main component that comes into contact with the floor. Made from materials such as rubber, plastic, or metal, depending on the application.

- Axle: Connects the wheel to the caster frame and allows for smooth rotation.

- Bearing: Ensures the wheel rolls smoothly and reduces friction.

- Frame (Yoke): The structure that holds the wheel and attaches to the furniture.

- Mounting Plate: Connects the caster to the furniture, available in various styles such as top plates, stems, or threaded rods.

Each part of a furniture caster plays a critical role in its overall performance. Understanding the function and importance of each component can help in choosing the right caster for specific applications.

| Component | Description |

|---|---|

| Wheel | The wheel material affects the caster's performance on different surfaces. |

| Axle | The axle is the shaft that holds the wheel in place and allows it to rotate. |

| Bearing | Bearings reduce friction between the wheel and the axle, allowing the caster to roll smoothly. |

| Frame (Yoke) | The frame, or yoke, holds the wheel and attaches to the mounting plate. |

| Mounting Plate | The mounting plate connects the caster to the furniture. |

Common Materials for Furniture Casters

Furniture casters are made from various materials, each offering different benefits and suited for specific applications. Choosing the right material ensures optimal performance, durability, and protection for flooring.

| Material | Description | Applications |

|---|---|---|

| Rubber | Provides a smooth, quiet ride and protects floors from scratches. Ideal for delicate floors like hardwood and tile. | Office chairs, rolling tables, medical equipment |

| Plastic | Durable and resistant to chemicals. Suitable for a variety of surfaces including carpet, hardwood, and concrete. | Light-duty furniture, office equipment, household items |

| Polyurethane | Versatile and durable, providing a smooth ride on various surfaces. Excellent load-bearing capacity and floor protection. | Industrial carts, office furniture, hospital beds |

| Nylon | Lightweight and strong, resistant to wear and abrasion. Ideal for environments where chemicals are used. | Laboratory equipment, food service carts, medical devices |

| Thermoplastic Rubber (TPR) | Combines the benefits of rubber and plastic, offering a quiet ride and excellent floor protection while being resistant to chemicals and wear. | Medical equipment, office chairs, lightweight carts |

European Standards for Casters

In the caster industry, several European standards serve as guidelines to ensure the quality, safety, and environmental compatibility of products. Here, we provide an overview of some pivotal standards that are commonly adhered to:

| Standard | Description | Function Tested | Qualification Criteria | Testing Machine |

|---|---|---|---|---|

| EN840 | Applies to mobile waste containers with capacities up to 1700 liters used by the general public. Specifies essential dimensions for interoperability with lifting devices. | Interoperability and dimensional accuracy | Containers must fit standardized lifting devices and maintain structural integrity under load | Dimensional measurement devices and load testing machines |

| PAHs (Polycyclic Aromatic Hydrocarbons) | Governs the restriction of PAHs in consumer products, including casters and wheels. | Chemical content analysis | PAH concentration must be below specified limits (e.g., <1 mg/kg) | Gas chromatography-mass spectrometry (GC-MS) |

| REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) | Addresses the production and use of chemical substances and their potential impacts on human health and the environment. | Chemical composition and safety assessment | Compliance with REACH Annex XVII and authorization list requirements | High-performance liquid chromatography (HPLC), safety data sheet (SDS) review |

| RoHS (Restriction of Hazardous Substances) | Restricts the use of specific hazardous materials found in electrical and electronic products. | Presence of hazardous substances (e.g., lead, mercury, cadmium) | Concentration of restricted substances must be below 0.1% (1000 ppm) except cadmium, which must be below 0.01% (100 ppm) | X-ray fluorescence (XRF) spectroscopy, inductively coupled plasma mass spectrometry (ICP-MS) |

| EN 12530 | Outlines requirements and dimensions for equipment casters and manually operated wheels used in public facilities. | Dimensional accuracy, load-bearing capacity, and durability | Casters must meet specified dimensions, support specified loads without failure, and pass durability tests (e.g., rolling resistance, swivel resistance) | Universal testing machines (UTM), endurance testing rigs, dimensional measurement devices |

These standards are integral in guiding manufacturers to produce products that are not only of high quality but also safe and environmentally responsible. Adherence to these standards is often seen as a mark of reliability and trustworthiness in the industry.

Understanding the Lifecycle of Casters

In the realm of caster usage, understanding the lifecycle of casters is pivotal in planning proactive maintenance or replacements, thereby mitigating potential risks associated with caster failures. Here, we delve into the various factors that influence the durability and lifespan of casters:

- Material Considerations: The materials used in the construction of casters significantly influence their lifespan. For instance, casters that frequently come into contact with water, corrosive liquids, or air tend to have a shorter lifespan. Moreover, the choice of material can also affect the caster's appearance over time. Utilizing stainless steel rigs, for example, can offer more years of service and maintain a better presentation of your product, preventing rust and corrosion that can reflect poorly on the facility's operation.

- Maintenance Practices: Proper maintenance practices can extend the lifecycle of casters. Regular check-ups and timely replacements can prevent issues such as inventory damage, product flow interruptions, and potential workplace injuries. It is recommended to change casters at certain intervals to avoid downtime caused by machinery or cart failures.

- Appropriate Caster Selection: Choosing the right caster for the specific job at hand is crucial. Different applications demand different types of casters, and selecting the appropriate one can prevent premature wear and tear, thereby extending the caster's lifespan.

- Environmental Factors: The environment in which the caster operates can also affect its durability. Factors such as exposure to water and corrosive liquids can shorten the caster's lifespan. Hence, understanding the specific environmental conditions and selecting casters accordingly can be beneficial in prolonging their service life.

For further information or assistance in selecting and maintaining casters, our professional sale’s advice is available to guide you in making informed decisions.

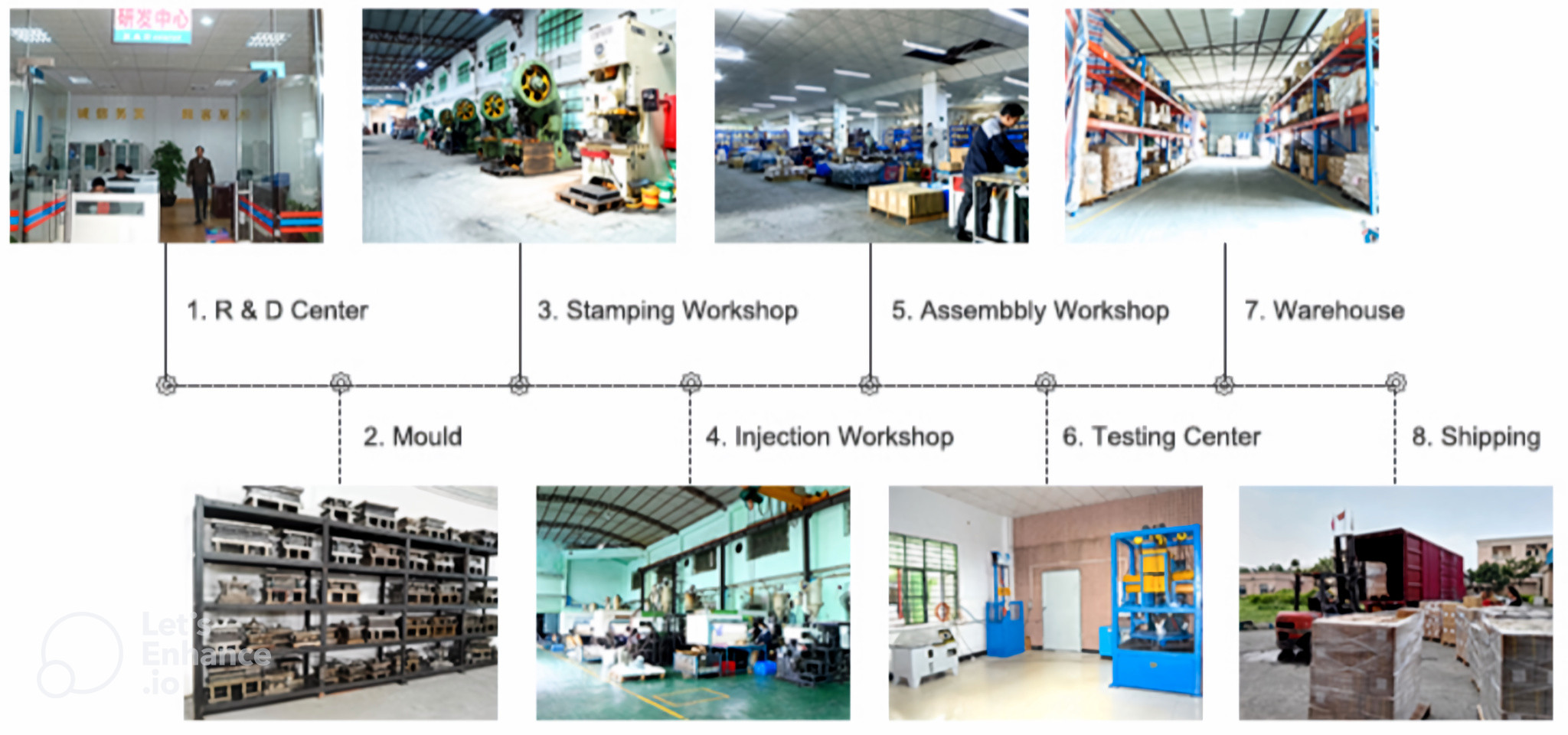

Casters End-to-End Production Process

Caster and wheel, often overlooked, are integral to various aspects of daily life. From shopping carts to industrial equipment, these simple yet efficient components serve as the unsung heroes of mobility. The production process behind caster wheels is a blend of cutting-edge technology and expert craftsmanship.

Research and Development: It all begins with innovation at the Research and Development Center. Engineers and designers continuously explore new materials and methods to enhance caster wheel performance.

Mold Creation: Precision is the focus in mold creation. Skilled artisans employ advanced technology to craft molds that define the dimensions of caster wheels.

Stamping and Injection Workshops: In these workshops, high-tech machines transform raw materials into caster components. Stamping creates durable metal pieces, while injection molding produces resilient plastic parts.

Assembly Workshop: Skilled workers meticulously assemble the caster wheels, ensuring they roll smoothly and securely.

Testing Center: Quality assurance is critical. Each caster wheel undergoes rigorous testing to meet and exceed industry standards. These tests evaluate the wheels' performance, durability, and safety, ensuring they can withstand real-world conditions.

Warehouse: Approved caster wheels are temporarily stored in an organized warehouse, awaiting distribution.

Shipping: Finally, these wheels are shipped worldwide, providing effortless mobility for various applications.

In this process, innovation and precision combine to make caster wheels an essential part of our daily lives.

Guiding Principles for Selecting Casters

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment.

| Consideration | Description |

|---|---|

| Purpose | Determine the specific function the caster will serve, such as mobility, stability, or braking. |

| Load Capacity | Ensure the caster can support the weight of the furniture and any additional loads. |

| Floor Compatibility | Choose a caster wheel material that won't damage the flooring. |

| Mounting Method | Select the appropriate mounting option for your furniture. |

| Durability | Consider the materials and construction quality for long-lasting performance. |

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment.

We also outline a systematic approach to guide you through the process of selecting and installing casters:

- Determine Your Product and Mounting Type: The first step involves identifying the type of product you are working with and the appropriate mounting method. Different products may require varied mounting techniques, and understanding this is crucial in selecting the right caster.

- Understanding Load Capacity: Before selecting a caster, it is essential to determine the load capacity it needs to handle. The load capacity is calculated using a specific formula that considers various factors including the deadweight of the transport unit, the maximum additional load, and the number of wheels or casters used. Safety factors, influenced by the speed and the ratio between wheel diameter and height of the obstacles, also play a significant role in determining the load capacity.

- Select Your Tread Material: The tread material significantly influences the operational comfort, smooth-rolling performance, and resistance characteristics of the wheels or casters. It is vital to choose a tread material that is softer than the floor to prevent damage.

- Determine Maneuverability: Understanding the maneuverability factors such as starting, rolling, and swivel resistance is crucial in selecting the right caster. These factors are influenced by various elements including wheel diameter, load, floor condition, and bearing type.

- Select the Bearing Type: The bearing type is a critical aspect that affects the rolling characteristics of a wheel. Different bearing types, such as plain bore bearing, roller bearing, and central ball bearing, offer varied performance characteristics and are suitable for different applications.

- Consider Your Application’s Environmental Influence: The environmental conditions where the caster will be used should be considered, especially in cases where the components may come into contact with aggressive substances. Factors such as chemical resistance, temperature, and humidity can influence the choice of caster.

- Additional Options and Requirements: Depending on your specific needs, you might require additional features such as locking systems for rolling and/or swivel motions, or brake systems. Understanding these additional requirements is vital in selecting the right caster.

Common Pitfalls When Buying Castors and Wheels

Ordering casters and wheels for your business might seem straightforward, but there are several common pitfalls that can complicate the process, especially for hardware supermarket buyers and caster distributors in Europe. Being aware of these issues can save you time, money, and resources while ensuring that you receive products that meet your specific needs.

- Ignoring Quality Standards

- Narrow Product Selection

- Lack of Custom Options

- Poor Communication

- Unclear Payment Structure

Getting the right casters and wheels for your business is more than just clicking ‘Get A Quote’. It’s about making smart choices, and that’s where Techin comes into play. We offer you a wide range of top-notch products, flexible custom options, and straightforward payment plans, all while keeping the lines of communication open.

By choosing Techin, you’re opting for a supplier that gets the ins and outs of the B2B world. We’re here to make your buying process hassle-free and help you steer clear of common mistakes, setting you up for success in your business.

Frequently Asked Questions

To continue to provide valuable information for our B2B clients, here are another ten FAQs that delve deeper into the aspects that most concern our target customers.

Do you offer free samples?

Yes, we offer product samples to give you a firsthand experience of the quality and variety we bring to the table.

Do you have any certifications?

Certainly, our products proudly bear recognizable certifications like EN840, REACH, RoHS, PAHs, EN12530 etc. These symbols of excellence guarantee that you receive products that meet international standards.

Is there a warranty period for your products?

All of our products come with a standard warranty period, reinforcing our commitment to quality and customer satisfaction.

How do you ensure timely delivery of orders?

We have a streamlined production schedule and robust logistics partnerships to ensure that your orders are delivered on time, every time.

Is it OK to print my logo on casters ?

Sure. We could build the molds and fixtures upon your sample or technical drawings, add your logo on fork or wheel, and pack the casters in your branded carton