Caster wheels for scaffolding are a must-have for construction, industrial maintenance, and other industries. They help scaffolds move around job sites safely, smoothly, and efficiently. Picking the right caster wheels for your scaffolding system is critical because they affect safety, durability, and how well your project goes. In this guide, we’ll take a deep dive into scaffolding caster wheels. We’ll cover the different types, parts, uses, and the advantages of using high quality ones.

1. Introduction to Scaffolding Caster Wheels

1.1 Definition and Overview

Scaffolding caster wheels are heavy duty wheels specifically designed to help scaffolding systems move safely and securely. They attach to the base of the scaffold and allow it to roll without compromising its structural integrity. This is especially important on big projects where workers need to get to different areas at different heights easily. Scaffolding caster wheels are built to handle a lot of abuse. They can support a lot of weight while keeping the people working on the scaffold safe.

1.2 Why Choose Scaffolding Caster Wheels?

Scaffolding caster wheels offer several advantages that make them an essential choice for projects requiring flexibility, safety, and efficiency. Unlike standard wheels, scaffolding caster wheels are specifically engineered to handle heavy loads, withstand constant movement, and provide stability through specialized locking mechanisms. Here’s why they are the preferred choice:

- Enhanced Mobility: Scaffolding caster wheels allow scaffolds to be easily repositioned, enabling workers to move to different areas without disassembling the scaffold. This mobility is crucial in dynamic environments where scaffolds need frequent adjustments.

- Load-Bearing Capacity: Built with high-strength materials like steel and polyurethane, these wheels can support substantial weights, ensuring that scaffolds remain stable even with multiple workers and equipment.

- Safety Features: Most scaffolding caster wheels come equipped with locking mechanisms (single or dual locking) that prevent accidental movement, providing the stability required for work at height. These locks add a critical layer of safety, reducing the risk of falls or tip-overs.

- Durability: Scaffolding caster wheels are designed to withstand rough environments, such as construction sites, and can resist wear and tear caused by constant use. Their materials, typically high-grade steel and polyurethane, make them a long-lasting choice, reducing the need for frequent replacements.

1.3 Applications Across Different Industries

Scaffolding caster wheels are versatile components found in a variety of industries where mobility, stability, and safety are essential. Here are some of the primary industries where these wheels are indispensable:

- Construction and Building Maintenance: In construction, scaffolding caster wheels facilitate easy movement of scaffolds across job sites, making it simpler for workers to access different building sections without disassembling the scaffold structure. They are also used in maintenance work on tall buildings, where flexibility and repositioning are key.

- Industrial and Manufacturing: Scaffolding caster wheels are used in manufacturing plants for temporary structures that support repair work, installation, or assembly tasks. Their high load-bearing capacity is essential for holding heavy-duty scaffolds that support industrial equipment and tools.

- Event Setup and Stage Production: Scaffolding caster wheels are widely used in stage production and event setups, where flexibility and speed are essential. They allow stages, lighting, and sound equipment scaffolds to be easily moved, adjusted, and secured in place.

- Aerospace and Aircraft Maintenance: In the aerospace sector, scaffolding caster wheels are often used to move scaffolds around aircraft for repair, inspection, and assembly tasks. The wheels provide easy access to different areas of large aircraft, enhancing maintenance efficiency.

- Warehousing and Logistics: Warehousing facilities often use mobile scaffolding on caster wheels for inventory management, maintenance, and organization. These wheels make it easy to move scaffold structures around, optimizing space and enabling quick reconfigurations of storage layouts.

| Industry | Role of Scaffolding Caster Wheels |

|---|---|

| Construction & Maintenance | Facilitates movement across job sites; allows access to various building sections without scaffold disassembly. |

| Industrial & Manufacturing | Supports heavy-duty scaffolds for repairs, installations, and assemblies; essential for load-bearing capacity. |

| Event & Stage Production | Enables flexible, rapid movement for stages, lighting, and sound equipment; allows quick adjustments as needed. |

| Aerospace Maintenance | Provides easy scaffold movement around aircraft for repairs and inspections; improves access to all aircraft areas. |

| Warehousing & Logistics | Enhances scaffold mobility for inventory and layout reconfigurations; optimizes storage space and organization. |

2. Key Components of Scaffolding Caster Wheels

2.1 Housing (Frame and Fork) Material

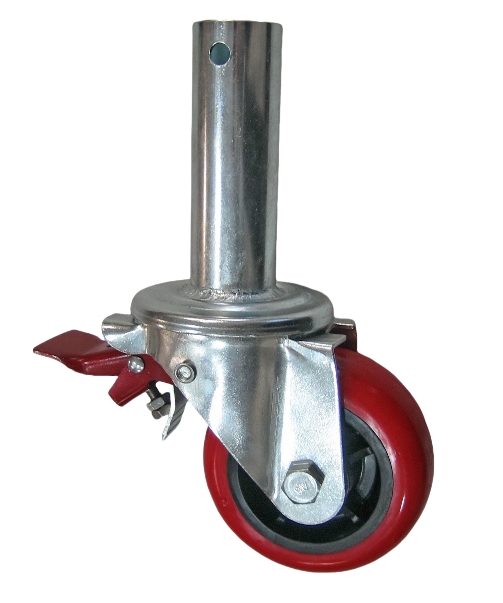

The housing, which includes the frame and fork, is typically made from high-strength materials like steel or cast iron. These materials provide the necessary support to bear the scaffold’s weight and withstand heavy-duty use. Steel and cast iron offer durability and stability, essential for maintaining scaffold safety and extending the lifespan of caster wheels even under constant movement. High-quality housing absorbs shocks and impacts, making it suitable for rough and uneven surfaces found on job sites.

2.2 Wheel Components and Design

Scaffolding caster wheels are often constructed from polyurethane or rubber for optimal shock absorption and durability. Polyurethane wheels, in particular, offer a smooth roll and excellent wear resistance, making them suitable for heavy duty applications on rough surfaces. Rubber wheels, while softer, are ideal for indoor settings where smooth movement is prioritized.

2.3 Locking Mechanisms in Scaffolding Caster Wheels

Locking mechanisms are essential for scaffolding caster wheels as they prevent accidental movement, thereby enhancing scaffold stability. There are several types of locking systems used in these wheels:

- Single Locking Mechanism: This type of lock secures the wheel in place, preventing it from rolling. However, it allows some swivel movement, which may be beneficial for minor adjustments but could lead to slight shifts in certain conditions.

- Dual Locking Mechanism: The dual lock prevents both rolling and swiveling, providing complete immobilization. This is particularly important for scaffolds used in elevated work environments, as it offers maximum stability and minimizes movement risk.

- Brake-Activated Mechanism: Some caster wheels come with a brake-activated system that allows workers to lock the wheels by applying downward pressure. This hands-free option provides a quick and efficient way to secure or release the wheels, saving time in fast-paced environments.

These locking mechanisms play a critical role in ensuring safety on construction sites, especially where stability is paramount to prevent potential accidents.

3. Types of Scaffolding Caster Wheels

3.1 Fixed vs. Swivel Scaffolding Caster Wheels

In scaffolding setups, fixed caster wheels offer excellent stability in applications where movement is limited to straight paths. These are best used for scaffolds that need to be moved in a single direction. Swivel caster wheels, however, allow 360-degree rotation, making them ideal for navigating tight spaces and maneuvering around obstacles on construction sites.

3.2 Medium Duty vs. Heavy Duty Scaffolding Caster Wheels

Heavy-duty scaffolding caster wheels are designed to bear substantial loads and are commonly used in industrial and commercial scaffolding where significant weight—such as equipment and building materials—is applied. Medium-duty caster wheels, while less robust, are sufficient for lighter scaffolding setups often used indoors or for maintenance work, where weight requirements are moderate.

3.3 Specialized Terrain Scaffolding Caster Wheels

The type of surface plays a significant role in selecting scaffolding caster wheels. Pneumatic caster wheels, which are air-filled, offer excellent shock absorption, making them ideal for uneven or rough outdoor surfaces. Solid wheels made from materials like polyurethane or rubber are better suited for smooth, flat surfaces, such as indoor floors. These wheels require minimal maintenance and are puncture-resistant, providing a reliable option for indoor applications.

4. Key Benefits of High-Performance Scaffolding Caster Wheels

4.1 Enhanced Mobility and Safety

High-quality caster wheels enable smooth, controlled movement of scaffolds, increasing both efficiency and safety. Non-slip treads and dual locking mechanisms provide extra security, especially on uneven surfaces or slopes, preventing unintended shifts and maintaining stability for those working on elevated platforms.

4.2 Durability and Resistance to Wear

Caster wheels designed with high-quality materials, like polyurethane or reinforced steel, resist wear and tear even under heavy loads and continuous use. Their durability reduces the need for frequent maintenance, saving time and costs while providing consistent performance throughout the scaffold’s lifespan.

4.3 Load Capacity and Weight Distribution

High-performance caster wheels are engineered to distribute weight evenly across the wheel’s surface, which helps minimize stress on specific areas of the scaffold. This is essential for applications where the scaffold bears significant loads, ensuring stability and preventing structural stress on the wheel assembly.

5. Performance Factors in Scaffolding Caster Wheels

5.1 Load Capacity and Distribution

Scaffolding caster wheels are built to handle substantial loads while ensuring balanced weight distribution. This minimizes localized stress, reducing wear and extending the wheel’s life, making them ideal for heavy-duty applications.

5.2 Speed and Frictional Resistance

Low-friction caster wheels improve maneuverability, reducing the energy required to move heavy scaffolds. This feature is particularly beneficial on large projects where powered mobility systems might be used, as it minimizes energy consumption.

5.3 Heat Resistance and Thermal Stability

The friction generated during scaffold movement and exposure to direct sunlight can impact wheel performance. High-quality materials, such as polyurethane, provide excellent thermal stability, allowing the wheels to perform reliably under varying temperatures.

6. Durability and Maintenance of Scaffolding Caster Wheels

6.1 Wear and Tear Resistance

Scaffolding caster wheels made from durable materials like polyurethane and cast iron are designed to resist deformation and scoring under heavy loads. This wear resistance reduces the frequency of replacements, ensuring that scaffolds remain safe and functional over time.

6.2 Maintenance Tips

To maintain optimal performance, scaffolding caster wheels require regular cleaning and lubrication. Cleaning removes dust and debris that could otherwise impair wheel function, while lubrication reduces friction, enhancing the wheels’ efficiency and longevity.

7. EN1004 Standards for Scaffolding Caster Wheels

7.1 What is EN1004?

EN1004 is a European safety standard that specifies the requirements for mobile access and working towers made of prefabricated components, commonly referred to as scaffolding towers. This standard outlines safety parameters, structural integrity, and load-bearing requirements for scaffolding, including caster wheels used on these mobile structures. EN1004 applies to towers that are free-standing and mobile, which makes it essential for any scaffolding system that incorporates caster wheels for mobility.

7.2 Key Requirements of EN1004 for Scaffolding Caster Wheels

The EN1004 standard emphasizes stability, load-bearing capacity, and overall safety for scaffolding towers. Key requirements for caster wheels under EN1004 include:

- Load-Bearing Capacity: Scaffolding caster wheels must support significant loads to prevent collapse or instability. Under EN1004, caster wheels are tested to ensure they meet the necessary weight capacities specific to the tower design and intended usage.

- Locking Mechanisms: To comply with EN1004, caster wheels must have effective locking mechanisms. Dual locking is often recommended to secure both the wheel’s roll and swivel, ensuring complete immobilization of the scaffold. This feature is crucial for preventing accidental movement during elevated work and on uneven surfaces.

- Durability and Material Standards: EN1004 specifies that caster wheels should be manufactured from durable, high-quality materials like steel and polyurethane. These materials are tested for resistance to wear, deformation, and environmental factors, ensuring long-lasting safety and stability.

- Adjustability: Caster wheels that meet EN1004 standards are often adjustable, allowing for height modifications to stabilize the scaffold on uneven surfaces. This adjustability is important for maintaining structural integrity and worker safety.

7.3 Why EN1004 Compliance is Important

EN1004 compliance is crucial for scaffolding systems in Europe and other regions that adopt European standards, as it ensures that scaffolding caster wheels are reliable, stable, and safe under real-world conditions. Compliance with EN1004 provides a level of assurance for contractors, safety inspectors, and workers, as it confirms that the scaffolding system meets stringent safety criteria. For projects involving mobile scaffolding, EN1004-compliant caster wheels reduce the risk of accidents, tip-overs, and structural failure, especially on elevated or high-load scaffolding setups.

8. People Also Ask

8.1 What are casters in scaffolding?

Casters in scaffolding refer to the wheels attached to the scaffold frame’s base, enabling mobility. These casters are engineered to support the scaffold’s load, allowing workers to reposition scaffolds easily without compromising safety. Many scaffolding casters include locking mechanisms to prevent accidental movement during use.

8.2 On what type of scaffold would you use a caster wheel?

Caster wheels are commonly used on mobile scaffolds, which are designed to be moved frequently. These mobile setups are beneficial in maintenance, painting, and light construction tasks where workers need flexibility. Caster wheels are not typically used on scaffolds that are intended to be stationary for extended periods or in highly elevated, non-mobile configurations.

8.3 What is the load capacity of heavy-duty scaffolding caster wheels?

Heavy-duty scaffolding caster wheels typically have load capacities ranging from 1,000 lbs to 2,500 lbs per wheel, depending on their construction and material. These high load capacities make them suitable for industrial and construction applications where scaffolds support significant weight.

8.4 Are scaffolding caster wheels adjustable?

Yes, many scaffolding caster wheels are adjustable, allowing workers to change the scaffold’s height or level. Adjustable caster wheels are especially useful on uneven surfaces, as they help to maintain scaffold stability by compensating for minor height discrepancies.

8.5 What is the 3 to 1 rule for scaffolding?

The 3 to 1 rule (or sometimes 4 to 1) is a safety guideline for scaffold stability, stating that the scaffold height should not exceed three times the width of the base. For example, if a scaffold base is 4 feet wide, the height should not exceed 12 feet unless it is secured to prevent tipping. This rule is critical when scaffolds are on caster wheels, as it prevents them from becoming top-heavy and risking a fall.

Summary

When you invest in high-quality scaffolding caster wheels, you get a lot of benefits. They make your scaffolding system safer, more durable, and easier to use. If you choose the right ones and take care of them, they can help you get more done and make your scaffolding system last longer, no matter what you’re using it for.