Sandwich Casters

Techin specializes in providing sandwich casters designed for demanding industrial and commercial applications. Our sandwich casters feature a unique multi-layer construction, combining materials like polypropylene (PP) and thermoplastic rubber (TPR), ensuring durability, noise reduction, and resistance to wear. These casters are perfect for environments such as manufacturing, warehousing, and logistics. Techin offers a wide range of customizable options to meet the specific requirements of your business. Contact us for more details or to request a custom quote.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Sandwich Casters

Techin’s sandwich casters offer a combination of materials that ensure high performance in heavy-duty environments. With a polypropylene core for strength and a thermoplastic rubber (TPR) outer ring for flexibility, our sandwich casters are designed to absorb shocks, reduce noise, and resist chemicals and wear. Whether you need them for machinery, transport carts, or logistics equipment, these casters deliver consistent performance and longevity.

Key Features of Sandwich Casters

- Durable Multi-Layer Design: Sandwich casters feature a robust multi-layer structure, combining the toughness of PP with the flexibility of TPR. This blend ensures superior durability, allowing the casters to withstand the wear and tear of heavy use in demanding environments. The outer TPR layer absorbs shocks, while the PP core provides structural integrity, making these casters ideal for industrial settings where strength and resilience are essential.

- Noise and Shock Reduction: The TPR layer of our sandwich casters is designed to reduce both noise and vibration, making them ideal for environments where quiet, smooth mobility is required. This feature ensures silent operation in noise-sensitive areas like hospitals or offices while providing protection against floor damage. The shock-absorbing properties of TPR also ensure a smoother ride for your equipment, reducing wear on both the caster and the surface.

- High Load Capacity: Techin’s sandwich casters are engineered to handle significant loads, making them the perfect choice for heavy-duty industrial equipment, machinery, and transport systems. Whether used in warehouses, factories, or logistics centers, these casters are built to manage high weight capacities without compromising performance or durability.

- Customizable Options: We understand that each business has unique needs, which is why Techin offers a variety of customization options for our sandwich casters. From different material combinations to a wide range of color schemes, our casters can be tailored to meet your specific operational requirements. Whether you need casters with higher shock absorption or specific aesthetic preferences, our engineering team can create the perfect solution for you.

These features make Techin’s sandwich casters the ideal choice for businesses in need of durable, high-performance caster solutions for industrial environments. Contact us today to learn more about our customizable options or to request a quote for your specific requirements.

Applications of Sandwich Casters

Sandwich casters are highly versatile and designed for a variety of industrial and commercial applications. Their durable multi-layer construction, combined with noise and shock-reducing features, makes them a reliable choice across multiple sectors.

Manufacturing & Warehousing

In manufacturing plants and warehouses, sandwich casters are essential for moving heavy-duty equipment and carts. Their robust design allows them to carry substantial loads while maintaining smooth mobility. The shock-absorbent TPR layer reduces wear and tear on both the casters and the floors, ensuring long-term performance in high-demand environments.

Logistics & Distribution

For logistics and distribution centers, sandwich casters excel in providing quiet and stable transport of goods. They are perfect for handling heavy loads, with the added benefit of noise reduction, which is particularly useful in fast-paced environments. Their ability to absorb shocks ensures that goods are moved safely and efficiently, even across uneven surfaces.

Medical Equipment

In medical settings, where quiet, smooth movement is vital, sandwich casters provide the stability and noise reduction necessary for medical carts, beds, and other equipment. The soft TPR layer allows for silent operation, reducing disruptions in hospitals and clinics while ensuring reliable, hygienic transport of sensitive items.

Exhibition and Event Equipment

For exhibitions and event setups, sandwich casters offer both mobility and aesthetic appeal. These casters ensure smooth movement for portable displays, booths, and event equipment. With customizable color options, they can be tailored to blend seamlessly with the overall design, maintaining a professional and polished look.

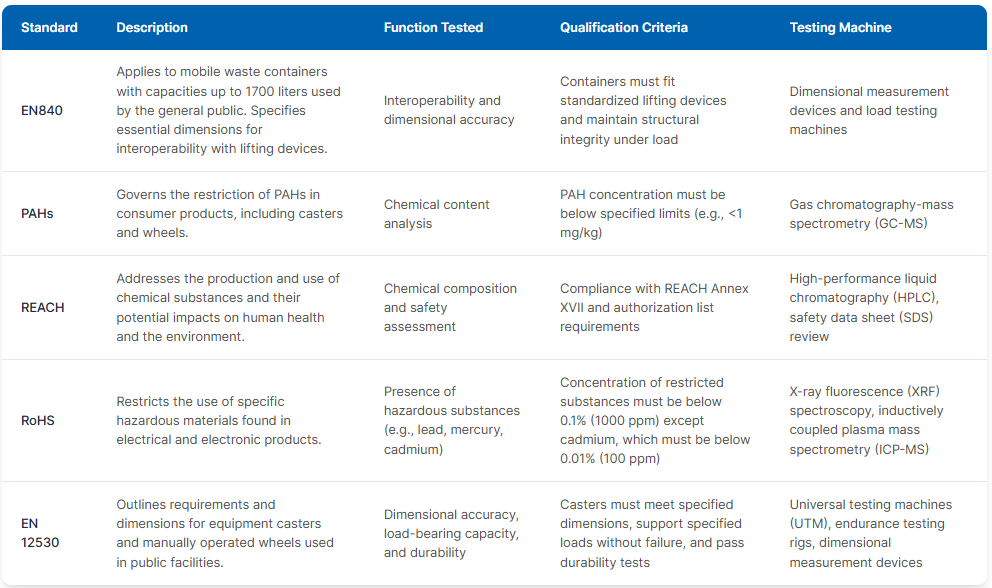

In the caster industry, several European standards serve as guidelines to ensure the quality, safety, and environmental compatibility of products. Here, we provide an overview of some pivotal standards that are commonly adhered to:

These standards are integral in guiding manufacturers to produce products that are not only of high quality but also safe and environmentally responsible. Adherence to these standards is often seen as a mark of reliability and trustworthiness in the industry.

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment.

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment.

We also outline a systematic approach to guide you through the process of selecting and installing casters:

- Determine Your Product and Mounting Type: The first step involves identifying the type of product you are working with and the appropriate mounting method. Different products may require varied mounting techniques, and understanding this is crucial in selecting the right caster.

- Understanding Load Capacity: Before selecting a caster, it is essential to determine the load capacity it needs to handle. The load capacity is calculated using a specific formula that considers various factors including the deadweight of the transport unit, the maximum additional load, and the number of wheels or casters used. Safety factors, influenced by the speed and the ratio between wheel diameter and height of the obstacles, also play a significant role in determining the load capacity.

- Select Your Tread Material: The tread material significantly influences the operational comfort, smooth-rolling performance, and resistance characteristics of the wheels or casters. It is vital to choose a tread material that is softer than the floor to prevent damage.

- Determine Maneuverability: Understanding the maneuverability factors such as starting, rolling, and swivel resistance is crucial in selecting the right caster. These factors are influenced by various elements including wheel diameter, load, floor condition, and bearing type.

- Select the Bearing Type: The bearing type is a critical aspect that affects the rolling characteristics of a wheel. Different bearing types, such as plain bore bearing, roller bearing, and central ball bearing, offer varied performance characteristics and are suitable for different applications.

- Consider Your Application’s Environmental Influence: The environmental conditions where the caster will be used should be considered, especially in cases where the components may come into contact with aggressive substances. Factors such as chemical resistance, temperature, and humidity can influence the choice of caster.

- Additional Options and Requirements: Depending on your specific needs, you might require additional features such as locking systems for rolling and/or swivel motions, or brake systems. Understanding these additional requirements is vital in selecting the right caster.

Sandwich casters combine strength, durability, and flexibility, making them ideal for industrial applications such as manufacturing, logistics, and medical equipment. With materials like polypropylene (PP) for structural support and thermoplastic rubber (TPR) for noise reduction and shock absorption, these casters offer excellent performance even in the most demanding environments. Their customizable options allow businesses to tailor casters to specific needs, ensuring both operational efficiency and long-term reliability. For more details on how Techin’s sandwich casters can enhance your operations, please contact us and our expert would give youe the professional solutions .

Frequently Asked Questions

To provide further clarity for our B2B clients, we’ve answered some common questions about sandwich casters. These answers are designed to address the most important concerns when selecting casters for industrial applications.

Do you offer customized sizes and materials for sandwich casters?

Yes, we provide customizable options for sizes, materials, and colors to meet the specific requirements of your industrial applications.

Do you have any certifications?

Certainly, our products proudly bear recognizable certifications like EN840, REACH, RoHS, PAHs, EN12530 etc. These symbols of excellence guarantee that you receive products that meet international standards.

What surfaces are suitable for sandwich casters?

Sandwich casters perform well on a variety of surfaces, including concrete, tile, and smooth factory floors, while preventing damage due to their shock-absorbent properties.

Can Techin provide OEM and ODM services for sandwich casters?

Yes, we offer both OEM and ODM services, allowing you to customize the design and branding of the casters according to your specific business needs.

Is it OK to print my logo on casters ?

Sure. We could build the molds and fixtures upon your sample or technical drawings, add your logo on fork or wheel, and pack the casters in your branded carton