Introduction

Sourcing caster wheels from China is a popular choice for businesses worldwide. The country has become a manufacturing powerhouse, offering a wide range of products at competitive prices. However, with so many options, it can be difficult to find the right manufacturer to meet your needs. In this guide, we’ll look at the key factors to consider when choosing a caster wheel manufacturer in China. By the end, you’ll know how to make an informed decision that leads to high-quality, reliable, and affordable products.

When choosing a caster wheel manufacturer in China, you need to consider factors such as the manufacturer’s experience, production capabilities, product range, quality assurance processes, and their ability to provide customized solutions. You should also understand the regional specialties within China so you can source the best products for your specific applications, whether you need furniture casters, industrial wheels, or heavy-duty castors.

Let’s explore why Chinese caster wheel manufacturers are popular with buyers around the world and the key factors you need to consider when choosing the right partner for your needs.

1. Why Choose Chinese Caster Wheel Manufacturers?

| Advantage | Description |

|---|---|

| Competitive Pricing | Cost-effective production allows for bulk purchases at low cost. |

| Manufacturing Expertise | Decades of experience ensure high-quality and reliable products. |

| Extensive Product Range | Wide variety of caster wheels for different applications. |

| Flexible Manufacturing | Customization options to meet specific needs. |

| Strong Global Supply Chain | Efficient, reliable worldwide delivery. |

Chinese manufacturers have a reputation for producing high-quality caster wheels at competitive prices, which is why so many businesses turn to them to optimize their procurement strategies. Here’s why you should consider sourcing caster wheels from China:

Competitive Pricing

China’s large-scale production capabilities and cost-efficient manufacturing processes enable manufacturers to offer caster wheels at prices that are often significantly lower than those of competitors in other countries. This cost advantage allows businesses to source high-quality products in bulk without breaking the bank, making Chinese manufacturers particularly attractive for companies with large-scale needs.

- Economies of Scale: The sheer volume of production in China means that manufacturers can leverage economies of scale, reducing the per-unit cost of caster wheels.

- Lower Labor Costs: Labor costs in China are generally lower compared to Western countries, contributing to the overall affordability of products.

- Cost-Effective Supply Chain: China’s well-developed supply chain infrastructure, including easy access to raw materials and efficient logistics networks, further drives down costs.

Manufacturing Expertise

China’s manufacturing industry is backed by decades of experience and continuous improvement, making it a global leader in caster wheel production. Manufacturers in China have honed their expertise, allowing them to produce a wide variety of caster wheels that meet international standards.

- Technical Know-How: Chinese manufacturers often employ skilled engineers and technicians who are experts in the design and production of caster wheels, ensuring products are both innovative and reliable.

- Continuous Improvement: The competitive nature of China’s manufacturing industry drives companies to constantly improve their processes, adopt new technologies, and enhance product quality.

- Global Standards: Many Chinese manufacturers adhere to international standards, such as ISO certifications, ensuring that their products are suitable for global markets.

Extensive Product Range

One of the standout features of Chinese manufacturers is their ability to offer an extensive range of caster wheels, catering to various industries and applications. Whether you need casters for furniture, industrial equipment, medical devices, or heavy-duty applications, you’re likely to find a manufacturer in China that specializes in the specific type of caster wheel you require.

- Diverse Applications: From light-duty casters for home furniture to robust wheels for heavy industrial machinery, the variety available in China is unmatched.

- Material Variety: Chinese manufacturers produce caster wheels in various materials, including rubber, polyurethane, nylon, cast iron, and more, each suited to different operating environments and load capacities.

- Size and Load Capacity: With a wide range of sizes and load capacities available, you can easily find caster wheels that meet the exact specifications of your project.

Flexible Manufacturing Capabilities

Chinese manufacturers are known for their flexibility, which is a significant advantage when you need customized solutions. Whether you need modifications to existing products or entirely new designs, Chinese manufacturers can often accommodate your requests with ease.

- Customization Options: Many manufacturers offer customization services, allowing you to specify details such as wheel material, size, load capacity, mounting type, and even color.

- Rapid Prototyping: The ability to quickly produce prototypes means that Chinese manufacturers can work closely with you to refine designs before full-scale production, ensuring the final product meets your exact needs.

- Scalable Production: Whether you need a small batch of specialized casters or a large order for mass production, Chinese manufacturers have the capacity to scale production according to your needs.

Strong Global Supply Chain

China’s position as a global manufacturing hub is supported by its robust supply chain infrastructure. This ensures that products can be shipped efficiently and reliably to destinations worldwide, minimizing delays and disruptions.

- Efficient Logistics: China’s advanced logistics networks, including ports, railways, and air freight services, facilitate the timely delivery of goods to international markets.

- Global Export Experience: Many Chinese manufacturers have extensive experience in exporting goods, meaning they are well-versed in handling international orders, customs documentation, and shipping logistics.

- After-Sales Support: Reliable manufacturers in China offer robust after-sales support, ensuring that any issues that arise after delivery are promptly addressed.

2. What Are the Key Factors to Consider When Evaluating Chinese Caster Wheel Manufacturers?

| Factor | Description |

|---|---|

| Experience & Reputation | Established manufacturers with a proven track record. |

| Production Capabilities | Advanced facilities with scalable production. |

| Product Range & Customization | Wide product variety and ability to offer tailored solutions. |

| Quality Assurance | Robust quality control with relevant certifications (e.g., ISO, CE). |

| Customer Service & Support | Responsive communication and comprehensive after-sales service. |

When selecting a caster wheel manufacturer in China, it’s important to conduct a thorough evaluation to ensure they can meet your specific requirements. Here are the key factors to consider:

Manufacturer’s Experience and Reputation

The experience and reputation of a manufacturer are strong indicators of their reliability and the quality of their products. A well-established manufacturer with a good track record is more likely to provide consistent quality and dependable service.

- Industry Experience: Look for manufacturers who have been in the caster wheel business for several years, as their experience is likely to translate into better product quality and customer service.

- Customer Reviews and Testimonials: Research online reviews and request references from the manufacturer. Positive feedback from previous clients can provide valuable insights into the manufacturer’s reliability.

- Case Studies and Portfolio: Ask the manufacturer for case studies or examples of similar projects they have completed. This can help you gauge their capability to meet your specific needs.

Production Capabilities

Assessing a manufacturer’s production capabilities is crucial to ensuring they can meet your order requirements, both in terms of volume and complexity. A manufacturer with advanced production facilities and skilled labor is more likely to deliver high-quality products on time.

- Manufacturing Facilities: Visit the manufacturing site if possible, or request a virtual tour. A well-equipped facility with modern machinery is a good indicator of the manufacturer’s production capabilities.

- Technology and Automation: Manufacturers that utilize the latest technology and automation in their production processes tend to produce more consistent and high-quality products.

- Scalability: Ensure the manufacturer has the capacity to scale production according to your needs, whether you require a small batch or a large volume of caster wheels.

Product Range and Customization

A manufacturer with a broad product range and the ability to offer customization is more likely to meet your specific needs. Customization options are particularly important if your project requires caster wheels with unique specifications.

- Product Variety: Evaluate the manufacturer’s catalog to see if they offer a wide range of caster wheels, including different sizes, materials, and load capacities.

- Customization Capabilities: Discuss your specific requirements with the manufacturer and inquire about their ability to customize products. This could include changes to the design, materials, or branding.

- Sample Production: Ask the manufacturer to produce samples of customized products before committing to a full order. This ensures that the final product meets your expectations.

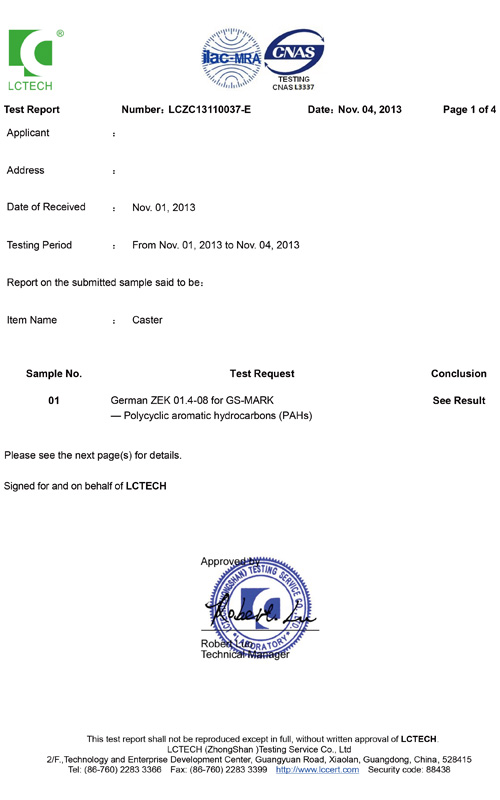

Quality Assurance

Quality assurance is critical when sourcing products from overseas. Ensure that the manufacturer has robust quality control processes in place to guarantee that every caster wheel meets the required standards.

- Certifications: Verify that the manufacturer holds relevant certifications, such as ISO 9001 for quality management systems. Certifications like CE, RoHS, and NSF are also important depending on the market and application.

- Testing Procedures: Inquire about the manufacturer’s testing procedures. Manufacturers that conduct rigorous testing, including load testing, durability testing, and material analysis, are more likely to produce reliable products.

- Inspection Reports: Request detailed inspection reports or third-party audits to verify the quality of the products before shipment.

Customer Service and Support

Good customer service is essential, especially when dealing with international suppliers. A manufacturer that offers excellent customer support can help navigate challenges such as communication barriers and time zone differences.

- Communication Channels: Ensure that the manufacturer is responsive and provides clear communication. Regular updates and open lines of communication are crucial for a smooth procurement process.

- After-Sales Support: Evaluate the manufacturer’s after-sales support services. This could include warranties, replacement policies, and support for any issues that arise after the sale.

- Dedicated Account Manager: Some manufacturers offer a dedicated account manager who will be your main point of contact throughout the process, providing personalized service and support.

3. Should I Source Different Types of Caster Wheels from Different Places in China?

| Region | Specialty Products |

|---|---|

| Zhongshan, Guangdong | Furniture casters, industrial casters. |

| Hebei Province | Heavy-duty casters, iron cast casters. |

| Qingdao, Shandong | Pneumatic wheels, foam wheels. |

| Zhejiang Province | Garbage bin casters. |

China’s vast manufacturing landscape means that different regions specialize in producing specific types of caster wheels. Sourcing from the right region can significantly impact the quality and suitability of the products for your needs.

Zhongshan, Guangdong

Zhongshan in Guangdong Province is renowned for its production of high-quality furniture casters and industrial casters. Manufacturers in this region have a long history of producing durable and stylish caster wheels for both domestic and international markets.

- Furniture Casters: Zhongshan is a major hub for furniture manufacturing, making it an ideal location for sourcing casters designed for furniture applications.

- Industrial Casters: The region also specializes in industrial casters that are built to withstand heavy loads and harsh environments, suitable for manufacturing and warehousing applications.

Hebei Province

Hebei Province is well-known for its production of heavy-duty casters and iron cast casters. If your project involves moving heavy machinery or equipment, sourcing from Hebei ensures you get the robust and reliable wheels you need.

- Heavy-Duty Casters: Hebei’s manufacturers produce casters designed to handle extreme weights, making them ideal for industrial and construction applications.

- Iron Cast Casters: These are particularly suitable for environments where durability and strength are paramount, such as in factories and workshops.

Qingdao, Shandong

Qingdao in Shandong Province is a key production center for pneumatic wheels and foam wheels. These types of wheels are essential for applications that require cushioning and shock absorption, such as in medical equipment or outdoor machinery.

- Pneumatic Wheels: Qingdao’s pneumatic wheels are designed to provide a smooth ride over uneven terrain, making them suitable for outdoor applications like trolleys and carts.

- Foam Wheels: Foam wheels from Qingdao offer a balance between durability and cushioning, ideal for indoor applications where noise reduction and floor protection are important.

Zhejiang Province

Zhejiang Province is a leading producer of garbage bin casters, which are essential for waste management systems. Sourcing from Zhejiang ensures you get casters that are both durable and easy to maneuver, perfect for both residential and commercial waste bins.

- Garbage Bin Casters: These casters are designed to be durable, corrosion-resistant, and capable of carrying heavy loads, making them ideal for waste management applications.

- Specialized Applications: Manufacturers in Zhejiang also offer casters for specialized applications, such as hospital waste bins, where hygiene and ease of movement are critical.

4. What Are the Common Issues to Avoid When Sourcing Caster Wheels from China?

While sourcing from China offers numerous benefits, there are potential pitfalls that you should be aware of to ensure a successful procurement process.

| Issue | Solution |

|---|---|

| Inconsistent Quality | Perform due diligence and request samples. |

| Communication Barriers | Provide clear specifications and maintain regular updates. |

| Hidden Costs | Request detailed quotations and clarify all terms upfront. |

| Lack of After-Sales Support | Ensure manufacturer offers good warranties and responsive support. |

Inconsistent Quality

Quality inconsistency can be a significant issue when dealing with overseas manufacturers. To avoid receiving substandard products, it’s crucial to perform thorough due diligence before placing an order.

- Quality Control Checks: Insist on multiple quality checks throughout the production process. Request documentation of these checks and consider hiring a third-party inspection service if necessary.

- Sampling: Always request samples before finalizing an order. This allows you to assess the product’s quality firsthand and make adjustments if needed.

- Long-Term Relationships: Building a long-term relationship with a trusted manufacturer can help ensure consistency, as manufacturers are more likely to maintain high standards for repeat customers.

Communication Barriers

Language differences and time zone challenges can lead to misunderstandings, which may affect the quality and timeliness of your order. Effective communication is key to overcoming these barriers.

- Clear and Detailed Specifications: Provide detailed specifications and instructions to avoid any ambiguity. Visual aids, such as diagrams or photos, can be particularly helpful.

- Regular Updates: Establish a regular communication schedule with your manufacturer to receive updates on the production process and address any issues promptly.

- Bilingual Staff: Working with a manufacturer that has bilingual staff can greatly enhance communication and reduce the risk of misunderstandings.

Hidden Costs

When sourcing from overseas, it’s important to be aware of all the costs involved to avoid any surprises. These costs can include shipping, duties, taxes, and additional fees that may not be included in the initial quote.

- Detailed Quotation: Request a detailed quotation that includes all potential costs, such as shipping, packaging, customs duties, and taxes.

- Shipping Terms: Clarify the shipping terms (e.g., FOB, CIF) to understand who is responsible for various costs and risks during transit.

- Currency Fluctuations: Be aware of currency exchange rates and how they might impact the final cost of your order.

Lack of After-Sales Support

After-sales support is crucial, especially when dealing with international suppliers. A manufacturer that provides comprehensive after-sales support can help address any issues that arise after delivery.

- Warranty and Return Policy: Ensure that the manufacturer offers a warranty and a clear return policy in case the products do not meet your expectations.

- Technical Support: Some manufacturers offer technical support to help with the installation or maintenance of their products. This can be particularly valuable for complex or customized orders.

- Responsive Customer Service: Choose a manufacturer with a reputation for responsive and helpful customer service, ensuring that any post-purchase issues are resolved quickly and efficiently.

5. How Important Is Customization in Choosing a Caster Wheel Manufacturer?

Customization is often a critical factor when selecting a caster wheel manufacturer, particularly if your application has unique requirements. A manufacturer that offers extensive customization options can provide products tailored to your specific needs, giving you a competitive edge in the market.

Meeting Specific Needs

Every application has different requirements, and off-the-shelf products may not always meet these needs. Customization allows you to specify the exact characteristics you need, such as wheel material, size, load capacity, and mounting type.

- Material and Design: Whether you need wheels made from a specific material for enhanced durability or a unique design for aesthetic purposes, customization can help you achieve your desired outcome.

- Load Capacity: Customizing the load capacity of the caster wheels ensures that they can handle the weight of your specific application without compromising performance.

- Environmental Considerations: For applications that involve exposure to harsh conditions, such as extreme temperatures or corrosive environments, customized wheels can be designed to withstand these challenges.

Branding and Design

Customization also extends to branding, allowing you to incorporate your company’s identity into the product. This can include adding logos, choosing specific colors, or designing wheels that match the overall aesthetic of your products.

- Brand Identity: Custom caster wheels with your brand’s logo and colors can enhance brand recognition and create a cohesive look across your product line.

- Design Differentiation: Unique designs can set your products apart from competitors, offering customers a distinctive choice that aligns with your brand values.

Competitive Advantage

In a crowded market, offering customized solutions can give you a significant competitive advantage. By providing products that are specifically tailored to your customers’ needs, you can differentiate your offerings and build a loyal customer base.

- Tailored Solutions: Customers are more likely to choose a product that meets their exact needs rather than a generic solution, making customization a key differentiator.

- Market Responsiveness: Customization allows you to quickly respond to market demands, offering specialized products that address emerging trends or specific customer requests.

6. Reliable Caster Wheel Manufacturers in China

When sourcing caster wheels from China, it’s essential to partner with reliable manufacturers known for their quality, innovation, and customer service. One such manufacturer that has earned a strong reputation in the industry is Techin Caster.

Techin Caster is a leading manufacturer of caster wheels in China, known for their commitment to quality and customer satisfaction. With 20 years of experience and a focus on continuous improvement, Techin Caster has become a preferred supplier for businesses worldwide.

- Extensive Product Range:

- Techin Caster offers a wide variety of caster wheels, catering to different industries and applications. From light-duty furniture casters to heavy-duty industrial wheels, Techin Caster has a product to meet every need. Their catalog includes a broad selection of materials, sizes, and load capacities, ensuring that customers can find the perfect fit for their specific requirements.

2. High-Quality Standards:

- Quality is at the core of Techin Caster’s operations. The company adheres to strict quality control processes throughout the production cycle, ensuring that every product meets international standards. Techin Caster’s commitment to quality is further demonstrated by the certifications they hold, including R, and RoHS, which attest to their products’ reliability and safety.

3. Customization Capabilities:

- Techin Caster understands that every customer has unique needs, which is why they offer extensive customization options. Whether you need a specific material, design, or load capacity, Techin Caster can tailor their products to meet your exact specifications. This flexibility makes them an ideal partner for businesses seeking bespoke solutions.

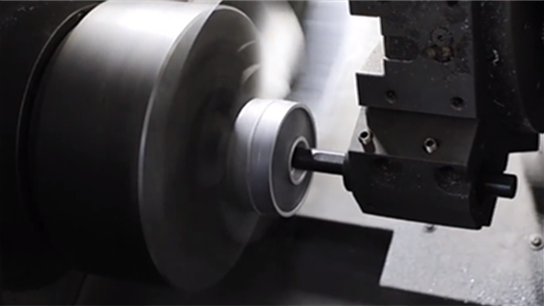

4. Innovative Manufacturing Techniques:

- Techin Caster utilizes advanced manufacturing techniques and state-of-the-art machinery to produce their caster wheels. Their investment in technology ensures that they can deliver high-performance products that are durable, reliable, and efficient. Continuous innovation is a hallmark of Techin Caster’s approach, allowing them to stay ahead of industry trends and meet the evolving needs of their customers.

5. Strong Customer Support:

- Customer satisfaction is a top priority for Techin Caster. They provide comprehensive customer support, from the initial inquiry to after-sales service. Their team is dedicated to helping customers find the right solutions and providing ongoing support to ensure long-term success.

6. Global Reach and Timely Delivery:

- With a robust global supply chain, Techin Caster is equipped to deliver products to customers around the world efficiently. Their logistics expertise ensures that orders are processed quickly and delivered on time, minimizing any potential disruptions to your operations. Techin Caster’s experience in handling international shipments means that customers can expect a smooth and hassle-free procurement process.

Conclusion

When it comes to sourcing caster wheels from China, partnering with a reliable manufacturer like Techin Caster can make all the difference. Their extensive product range, commitment to quality, and customer-centric approach ensure that you receive top-tier products tailored to your specific needs. By choosing Techin Caster, you can be confident in the quality and performance of your caster wheels, paving the way for successful and long-lasting business relationships.

Reach out to us at:

- Email: info@techincastor.com

- Phone/Whatsapp: +86 13417057114