Heavy Duty Casters

Techin has over 20 years in the industry, providing a wide array of high-quality heavy duty casters for various applications. Our products are subject to stringent quality control and are certified for dependability and safety. With an advanced automatic production line, Techin ensures precision, speed, and fast delivery to meet your business demands. Contact us today to request a free quote or additional information.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Heavy Duty Casters

Heavy Duty Casters are engineered to handle substantial weight loads, ranging from several hundred to several thousand kilograms. These casters are essential for demanding industrial applications, such as moving heavy machinery and equipment in manufacturing plants, Automotive Industry, and Aerospace Industry. Constructed with reinforced steel and advanced polymers, they offer exceptional durability and longevity. Precision bearings ensure smooth operation, even under significant loads, while their robust design guarantees reliable stability and maneuverability. Heavy Duty Casters are crucial for enhancing mobility, safety, and operational efficiency in various industrial settings.

Heavy Duty Casters and Wheels Applications

Heavy duty casters are indispensable across various industries, providing mobility, support, and efficiency for heavy equipment and machinery. Their versatility makes them essential for enhancing operational workflows, safety, and convenience. Below are some detailed applications of industrial casters in different sectors:

Manufacturing Plants

Industrial casters are crucial in manufacturing environments, facilitating the movement of heavy machinery, raw materials, and finished products. They are integral to production lines, allowing for the easy repositioning of equipment and materials. This mobility enables manufacturers to optimize their floor space, quickly adjust to production demands, and improve overall efficiency. Common uses include:

- Assembly Lines: Casters on conveyor systems and workbenches enable smooth transitions between different stages of production.

- Material Handling Carts: Used to transport raw materials and components to various production areas, reducing manual handling and enhancing productivity.

- Machinery Mobility: Heavy-duty casters on machinery and equipment allow for easy relocation and maintenance access.

Automotive Industry

In the automotive industry, industrial casters are essential for moving heavy parts, vehicles, and equipment within repair shops and manufacturing plants. They support various processes, including assembly, maintenance, and repair. Key applications include:

- Engine Stands: Casters on engine stands facilitate the movement of heavy engines for maintenance and assembly.

- Tool Carts: Mobile tool carts provide mechanics with easy access to tools and parts, enhancing efficiency.

- Vehicle Dollies: Used to maneuver vehicles within workshops, aiding in repairs and storage.

Aerospace Industry

The aerospace industry demands heavy-duty casters capable of handling substantial loads and providing precise movement for large components and equipment. Applications in this sector include:

- Aircraft Maintenance: Casters on maintenance platforms and tool carts ensure efficient servicing of aircraft.

- Component Transport: Heavy-duty casters enable the movement of large and heavy aerospace components within manufacturing and assembly areas.

- Ground Support Equipment: Mobile equipment used on airport tarmacs and hangars relies on robust casters for reliable performance.

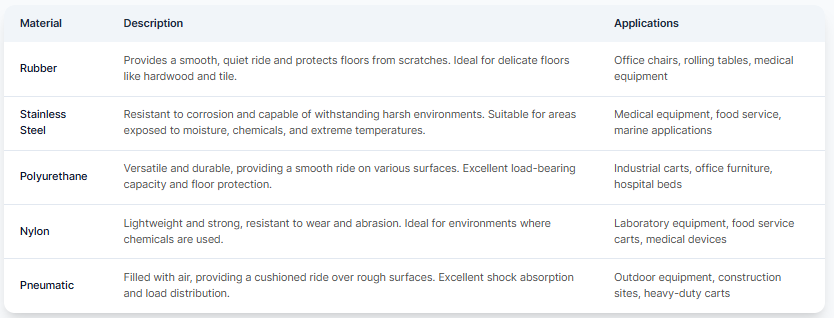

Industrial casters are made from various materials, each offering different benefits and suited for specific applications. Choosing the right material ensures optimal performance, durability, and protection for flooring.

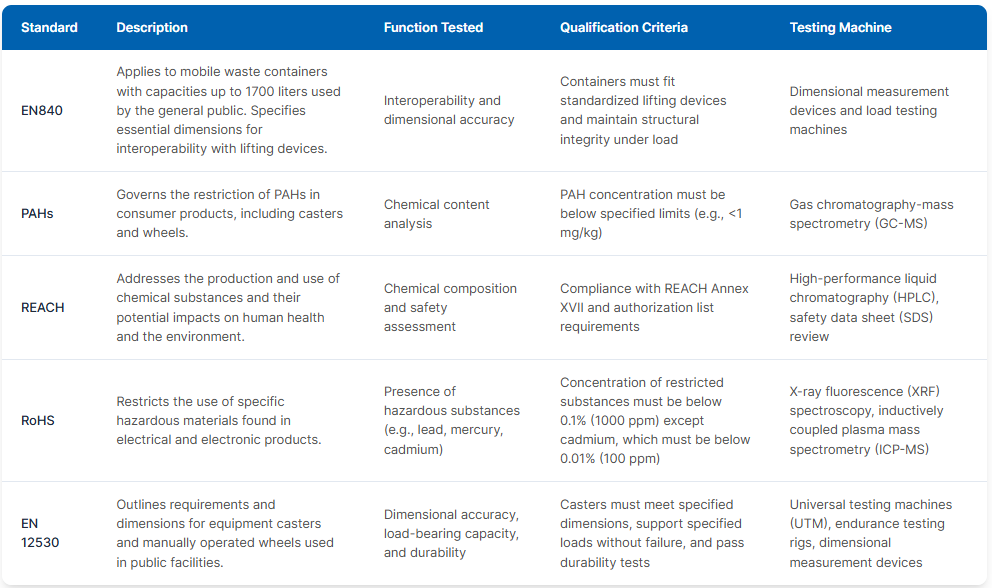

In the caster industry, several European standards serve as guidelines to ensure the quality, safety, and environmental compatibility of products. Here, we provide an overview of some pivotal standards that are commonly adhered to:

These standards are integral in guiding manufacturers to produce products that are not only of high quality but also safe and environmentally responsible. Adherence to these standards is often seen as a mark of reliability and trustworthiness in the industry.

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment.

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment.

We also outline a systematic approach to guide you through the process of selecting and installing casters:

- Determine Your Product and Mounting Type: The first step involves identifying the type of product you are working with and the appropriate mounting method. Different products may require varied mounting techniques, and understanding this is crucial in selecting the right caster.

- Understanding Load Capacity: Before selecting a caster, it is essential to determine the load capacity it needs to handle. The load capacity is calculated using a specific formula that considers various factors including the deadweight of the transport unit, the maximum additional load, and the number of wheels or casters used. Safety factors, influenced by the speed and the ratio between wheel diameter and height of the obstacles, also play a significant role in determining the load capacity.

- Select Your Tread Material: The tread material significantly influences the operational comfort, smooth-rolling performance, and resistance characteristics of the wheels or casters. It is vital to choose a tread material that is softer than the floor to prevent damage.

- Determine Maneuverability: Understanding the maneuverability factors such as starting, rolling, and swivel resistance is crucial in selecting the right caster. These factors are influenced by various elements including wheel diameter, load, floor condition, and bearing type.

- Select the Bearing Type: The bearing type is a critical aspect that affects the rolling characteristics of a wheel. Different bearing types, such as plain bore bearing, roller bearing, and central ball bearing, offer varied performance characteristics and are suitable for different applications.

- Consider Your Application’s Environmental Influence: The environmental conditions where the caster will be used should be considered, especially in cases where the components may come into contact with aggressive substances. Factors such as chemical resistance, temperature, and humidity can influence the choice of caster.

- Additional Options and Requirements: Depending on your specific needs, you might require additional features such as locking systems for rolling and/or swivel motions, or brake systems. Understanding these additional requirements is vital in selecting the right caster.

Frequently Asked Questions

To continue to provide valuable information for our B2B clients, here are another ten FAQs that delve deeper into the aspects that most concern our target customers.

Do you offer free samples?

Yes, we offer product samples to give you a firsthand experience of the quality and variety we bring to the table.

Do you have any certifications?

Certainly, our products proudly bear recognizable certifications like EN840, REACH, RoHS, PAHs, EN12530 etc. These symbols of excellence guarantee that you receive products that meet international standards.

Is there a warranty period for your products?

All of our products come with a standard warranty period, reinforcing our commitment to quality and customer satisfaction.

How do you ensure timely delivery of orders?

We have a streamlined production schedule and robust logistics partnerships to ensure that your orders are delivered on time, every time.

Is it OK to print my logo on casters ?

Sure. We could build the molds and fixtures upon your sample or technical drawings, add your logo on fork or wheel, and pack the casters in your branded carton