Introduction

PA6 caster wheels are a popular industrial component because they’re strong, they can take a hit, and they work in a lot of different places. Made out of polyamide 6 (PA6 or nylon 6), they’re great for places where you need something that can handle a lot of weight, can get beat up, and might get some chemicals on it. In this article, we’re going to talk about what PA6 caster wheels are, what they’re good for, and why they’re better than other materials in some places. We’ll also give you some tips on how to pick the right PA6 caster wheel for your stuff so it works great, lasts a long time, and doesn’t cost too much.

Understanding PA6 Caster Wheels

PA6 caster wheels are crafted from polyamide 6, a robust thermoplastic known for its high mechanical strength, impact resistance, and overall durability. In industrial settings, these qualities are invaluable. The wheels withstand significant weight, allowing machinery to transport heavy items smoothly, even over abrasive surfaces. Polyamide 6 also has natural self-lubricating properties, reducing friction, wear, and the frequency of maintenance.

Compared to other caster wheel materials, PA6 stands out due to its exceptional resilience. While alternative materials like polyurethane and polypropylene may work for specific tasks, PA6 offers an unmatched balance of strength, load-bearing capacity, and chemical resistance, making it ideal for industrial settings.

| Attribute | PA6 Caster Wheels | Polyurethane Caster Wheels | Polypropylene Caster Wheels |

|---|---|---|---|

| Strength and Durability | High tensile strength, withstands high loads | Moderate strength, softer surface, ideal for indoor floors | Brittle, lower load tolerance |

| Heat Resistance | Moderate, can handle mild heat exposure | Low to moderate, may soften under high temperatures | Poor, deforms under moderate heat |

| Abrasion Resistance | Excellent, especially on rough surfaces | Moderate, wears down under heavy, abrasive loads | Poor, wears quickly on rough or sharp surfaces |

| Chemical Resistance | Good, withstands oils, mild acids, and alkalis | Moderate, but can degrade with certain chemicals | Fair, more resistant to certain solvents |

| Applications | Ideal for industrial and rough environments | Common in warehouses with smooth floors | Light-duty, suited for clean, low-wear environments |

While polyurethane and polypropylene may suit specific environments, PA6’s properties make it the best option for situations that demand robust, lasting performance under heavy and frequent use.

Key Properties of PA6 Caster Wheels

The properties of PA6 caster wheels are what set them apart in industrial applications. Here are the primary attributes:

- Impact Resistance: PA6’s resilience to impact allows it to absorb shock without cracking. In environments with heavy or sudden impact, such as factories, PA6 wheels keep equipment moving without damage.

- Load-Bearing Capacity: PA6 caster wheels are engineered to support heavy loads, making them ideal for equipment used in material handling and industrial transport, where reliability under weight is essential.

- Abrasion Resistance: The high abrasion resistance of PA6 caster wheels ensures they last even when used on rough surfaces. This property contributes to their durability and reduces the frequency of replacements.

- Chemical Resistance: PA6’s ability to resist damage from exposure to oils, mild acids, and alkalis makes these wheels valuable in factory or laboratory settings, where they maintain integrity under chemical exposure.

- Temperature Tolerance: PA6 caster wheels perform reliably in both low and moderate temperatures, making them a versatile choice for both indoor and outdoor environments.

| Property | Description |

|---|---|

| Impact Resistance | Absorbs high impact, reducing crack risk and extending wheel lifespan |

| Load Capacity | Supports heavy weights without deformation |

| Abrasion Resistance | Resists wear and tear on rough or abrasive surfaces |

| Chemical Resistance | Withstands exposure to various chemicals, ideal for labs and factories |

| Temperature Range | Operates reliably in low to moderate temperatures |

The combination of these qualities makes PA6 wheels a reliable, low-maintenance solution for challenging environments.

Types and Applications of PA6 Caster Wheels

PA6 caster wheels are available in various types, each engineered to meet specific industrial needs. Here’s an overview of these types and their applications:

- Standard PA6 Wheels: The most versatile and cost-effective type, standard PA6 wheels provide a good balance of durability and strength. Commonly found on carts, assembly line equipment, and transport units, these wheels are an excellent all-around choice for most industrial applications.

- PA6 High-Temperature Wheels: Designed to handle higher temperatures than standard PA6 wheels, these are often used in food processing, where equipment undergoes frequent sterilization or cleaning. Their resistance to temperature prevents them from softening, ensuring reliable performance.

- Anti-Static PA6 Wheels: These wheels are treated to prevent static buildup, making them ideal for electronics manufacturing or laboratories where static can pose risks to sensitive equipment.

- Heavy-Duty PA6 Wheels: Engineered for extreme weight, these heavy-duty PA6 wheels are reinforced to handle substantial loads. They are frequently used in forklifts, industrial carts, and other heavy equipment applications.

| Type | Key Features | Applications |

|---|---|---|

| Standard PA6 Wheels | Durable, impact-resistant | Warehouses, assembly lines, industrial transport |

| High-Temperature PA6 | Resistant to moderate heat | Food processing, high-temperature sterilization |

| Anti-Static PA6 Wheels | Static resistance | Electronics manufacturing, labs |

| Heavy-Duty PA6 Wheels | Extra load capacity, durable | Forklifts, industrial carts |

Each type of PA6 caster wheel offers unique advantages, allowing users to tailor their selection to specific operational demands.

Advantages of PA6 Caster Wheels

The benefits of PA6 caster wheels make them an optimal choice for demanding environments. Below is an expanded look at each advantage:

- Cost-Effective Durability: PA6 wheels are built to last, even under frequent, heavy use, which reduces the frequency and cost of replacements. Their durability translates to a lower total cost of ownership over time.

- Environmental Resilience: These wheels are naturally resistant to moisture and chemicals, meaning they perform well in environments with exposure to elements. PA6 wheels won’t swell, shrink, or deform, preserving their shape and function.

- High Load Capacity: With a dense structure, PA6 caster wheels are reliable for high-demand industrial applications, particularly in settings where equipment handles substantial weight or moves heavy goods.

- Noise Reduction: PA6 material absorbs sound, creating a quieter work environment. This noise reduction feature is particularly valuable in settings where noise control contributes to worker comfort and productivity.

These benefits have made PA6 caster wheels a preferred choice in settings that demand performance, longevity, and cost-effectiveness.

Cost Efficiency and Longevity of PA6 Caster Wheels

PA6 caster wheels are an investment in both performance and cost savings, offering durability that translates into long-term financial benefits. Here’s how PA6 wheels contribute to cost efficiency and operational longevity:

- Extended Service Life: The high durability of PA6 material means these wheels are resistant to wear, impact, and abrasion, ensuring a long lifespan even in heavy-duty applications. Their longevity reduces the frequency of replacements, making PA6 wheels a cost-effective option over time.

- Lower Maintenance Costs: PA6 caster wheels require minimal upkeep, reducing maintenance costs and downtime. Their natural resistance to environmental factors like moisture, chemicals, and temperature fluctuations helps maintain performance without frequent intervention, further decreasing operational expenses.

- Reduced Floor Maintenance: With non-marking and low-abrasion properties, PA6 caster wheels are gentle on flooring. This minimizes floor wear and tear, reducing repair and replacement expenses over time, especially in high-traffic areas like warehouses, hospitals, and manufacturing floors.

- Energy Efficiency in Motorized Applications: PA6 wheels, due to their low rolling resistance, require less energy for movement. When used with motorized equipment, they contribute to lower power consumption, helping to cut energy costs in operations where equipment is frequently in motion.

- Improved ROI: By investing in PA6 caster wheels, companies can see a positive return on investment through lower overall maintenance, repair, and replacement costs. The combination of durability, energy efficiency, and minimal upkeep makes PA6 wheels a valuable asset for businesses aiming to maximize the lifecycle of their equipment.

| Cost Efficiency & Longevity Benefit | Description |

|---|---|

| Extended Service Life | Durable design reduces replacement frequency, saving long-term costs |

| Lower Maintenance Costs | Minimal upkeep needed, decreasing downtime and maintenance expenses |

| Reduced Floor Maintenance | Non-marking properties protect floors, lowering floor repair costs |

| Energy Efficiency | Lower rolling resistance saves energy, especially in motorized applications |

| Improved ROI | Combines cost-saving factors to maximize the return on investment |

These factors make PA6 caster wheels an economical choice for industries seeking to reduce operational costs while maintaining high-performance standards. The extended service life and reduced maintenance requirements of PA6 wheels allow businesses to allocate resources more effectively, achieving significant cost savings over the wheels’ lifetime.

Main Uses of PA6 Caster Wheels

Due to their versatility and robust properties, PA6 caster wheels are integral to various industries. Here are the primary applications:

- Warehousing and Logistics: Used on carts, pallets, and other transport equipment, PA6 wheels make moving goods efficient in warehouses. Their strength and impact resistance support continuous, heavy use.

- Food Processing: In food production environments, PA6 wheels’ chemical and temperature resistance make them suitable for regular cleaning and exposure to harsh sanitizing agents. Their durability and ease of maintenance are especially beneficial in environments where sanitation is critical.

- Medical Equipment: In healthcare settings, PA6 wheels are used in equipment such as hospital beds and medical carts, where they contribute to a quieter, smoother operation. This noise reduction feature is highly valued in healthcare, creating a more comfortable setting for patients.

- Automotive and Manufacturing: PA6 wheels’ load-bearing capacity and toughness make them suitable for assembly lines and heavy machinery, where reliable performance is essential for efficient production.

- Electronics: Anti-static PA6 wheels prevent static buildup, making them ideal for electronics assembly and manufacturing. By reducing the risk of electrostatic discharge, these wheels help protect sensitive components.

| Industry | Use of PA6 Caster Wheels |

|---|---|

| Warehousing & Logistics | Used on carts, pallets, and heavy-duty transport equipment |

| Food Processing | Suitable for equipment needing frequent cleaning and chemical resistance |

| Medical Equipment | Ideal for beds, carts, and equipment requiring noise reduction |

| Automotive & Manufacturing | Supports machinery and assembly lines, durable for long use |

| Electronics | Prevents static buildup, safe for electronics assembly |

These varied applications highlight PA6 caster wheels’ adaptability and value across many industries.

Choosing High-Quality PA6 Caster Wheels for Optimal Performance

At Techin, we offer a diverse selection of PA6 caster wheels designed to meet the specific needs of various industries. Our products combine the exceptional qualities of PA6 with additional materials to create versatile, durable wheels for industrial, commercial, and specialized applications. Here’s a look at our key products:

- White PA6 Wheel Casters: These wheels are crafted from pure PA6, delivering high impact resistance, excellent load-bearing capacity, and long-lasting durability. The clean, white design is ideal for applications requiring aesthetics alongside functionality, commonly found in food processing and medical equipment.

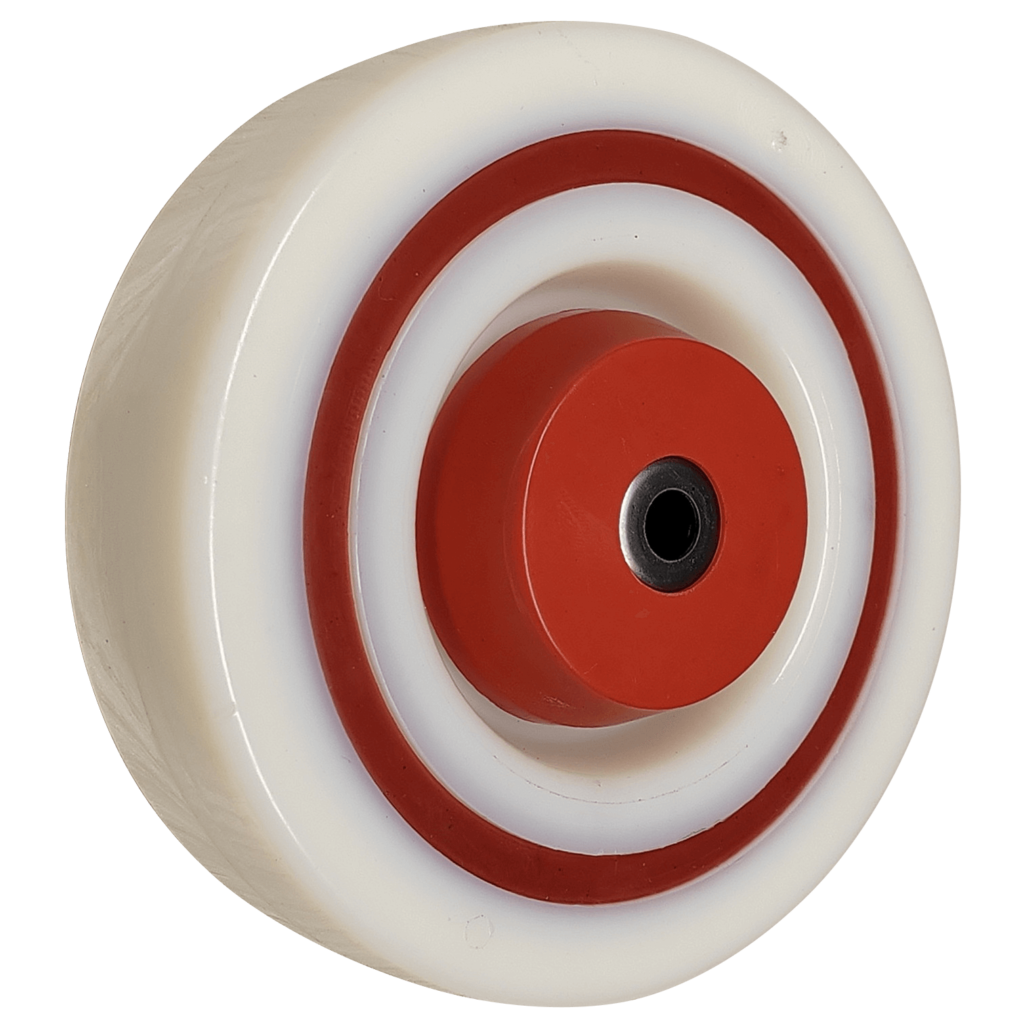

- Red and White PU+PA6 Wheel Casters: These wheels combine the strength of PA6 with a polyurethane (PU) coating, offering an added layer of softness and shock absorption. The PU coating provides extra floor protection and minimizes noise, making these casters suitable for environments such as warehouses, hospitals, and retail spaces where a quieter, non-marking wheel is needed.

- Black TPU+PA6 Casters: With a thermoplastic polyurethane (TPU) outer layer, these black PA6 wheels are designed for heavy-duty applications that require a balance of strength, flexibility, and abrasion resistance. TPU+PA6 casters are excellent for handling high loads while maintaining smooth and quiet mobility, ideal for manufacturing and logistics.

- PA6 + Rubber Sandwich Casters: These innovative wheels incorporate a rubber layer between PA6 materials, creating a “sandwich” structure that provides enhanced shock absorption, grip, and floor protection. The PA6 + rubber combination is highly effective in environments that require both durability and vibration reduction, such as automotive production and material handling in uneven terrain.

By combining different materials with the strength of PA6, we make wheels that work on all kinds of floors, from smooth inside floors to rough outside floors. Each of these caster wheels is made for a different reason, so you can find the one that works best for your stuff and what you do.

For more information on our PA6 caster wheels or to explore how they can meet your needs, contact our team for personalized assistance. We’re here to help you optimize your operations with durable, reliable, and high-performance PA6 caster wheels.

People Also Ask

Is PA6 the same as nylon 6?

- Yes, PA6 is the technical abbreviation for polyamide 6, commonly known as nylon 6. They are the same material, a type of synthetic thermoplastic known for its high tensile strength, impact resistance, and versatility in various applications. PA6 (or nylon 6) is used widely for caster wheels because of its durability and adaptability to challenging industrial environments.

How resistant is PA6 to chemicals, and which chemicals can it withstand?

- PA6 has good chemical resistance, especially against oils, greases, and mild acids, which makes it suitable for industrial and laboratory settings. It is resistant to many cleaning agents, organic solvents, and alkalis, allowing it to function well in environments with frequent chemical exposure. However, it may have limitations against strong acids or highly concentrated bases, so these factors should be considered based on the specific application.

What is the temperature range for PA6 caster wheels, and how does it impact performance?

- PA6 caster wheels operate effectively across a wide temperature range, typically from -30°C to about 120°C (-22°F to 248°F), maintaining their shape and performance. This broad range allows them to be used in both cold storage and moderately hot environments without risk of deformation or loss of strength, making them versatile for industries with temperature-sensitive operations.

How does the impact resistance of PA6 caster wheels benefit industrial applications?

- PA6 caster wheels have excellent impact resistance, which means they can withstand sudden pressure or shock without cracking or deforming. This quality is essential in industrial applications where equipment or carts encounter frequent jolts, such as on uneven surfaces or in high-speed operations. The impact resistance contributes to longer wheel life, reduces maintenance needs, and enhances safety by minimizing the risk of wheel failure.