When it comes to choosing the right caster wheel for your needs, the material used in the caster wheel hub is a big factor in how well it performs and how long it lasts. Whether you’re moving heavy machinery, office furniture, or light carts, knowing the different materials used in caster wheel hubs will help you make the best choice for strength, mobility, and durability. In this guide, we’ll break down the materials used in caster wheel hubs, their pros and cons, and how to choose the right one for your specific application.

Caster wheel hubs are the central parts of casters that hold the wheel and allow it to rotate. They’re usually made from materials like steel, aluminum, cast iron, nylon, and PVC. Each of these materials has its own advantages. Steel and cast iron are great for heavy duty applications because they have a high load-bearing capacity. Nylon and PVC hubs are lighter, quieter, and resistant to corrosion, which makes them great for lighter or quieter operations.

Now that you have a basic understanding of caster wheel hubs and their materials, let’s dive into how each material affects caster performance and how to choose the right one for your application.

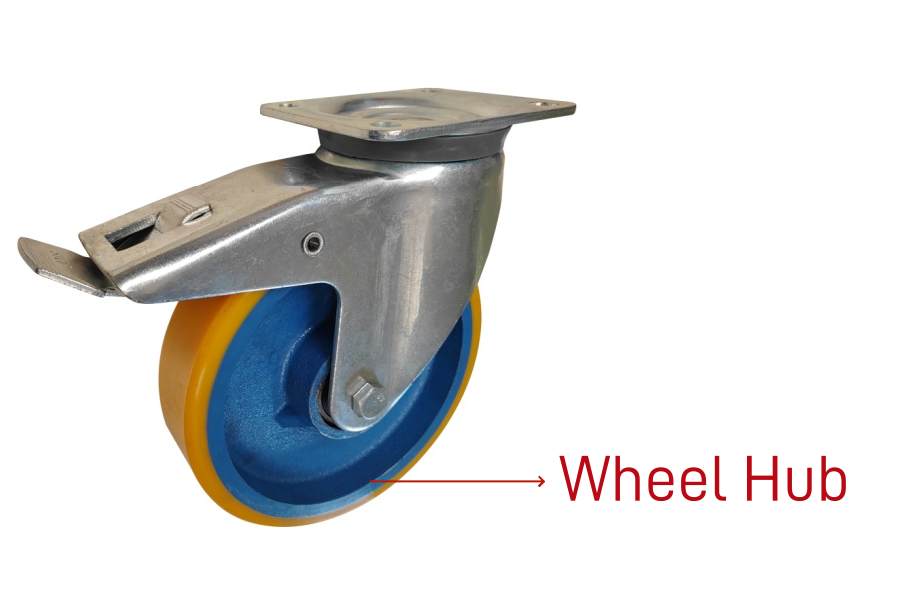

1. What Are Caster Wheel Hubs?

Caster wheel hubs are the core components of a caster, responsible for supporting the wheel and enabling it to rotate. Without a hub, the wheel cannot function as intended. Caster hubs are made from various materials, including steel, aluminum, cast iron, nylon, and PVC, each chosen based on the specific performance requirements of the caster.

The hub is typically mounted onto a caster frame, and it is the part that interacts with the axle, allowing the wheel to turn smoothly. The material of the hub is crucial in determining the caster’s overall performance, especially when it comes to load-bearing capacity, durability, rolling resistance, and environmental adaptability.

2. How Do Caster Wheel Hub Materials Affect Caster Performance?

The material of a caster wheel hub plays a crucial role in determining its overall performance across various factors, including durability, load capacity, noise and vibration, and corrosion resistance. The hub is responsible for connecting the wheel to the axle, and its material affects how the caster behaves under different conditions.

- Durability: The hub material affects how well a caster can withstand wear and stress. Stronger materials like steel provide more durability, making them suitable for heavy-duty applications. Softer materials, such as plastic, may wear down faster under constant use or heavy loads.

- Load Capacity: The hub material determines how much weight a caster can bear. Metal hubs, like steel, can support heavier loads without deforming, while plastic hubs are better for lighter-duty applications. For example, plastic hubs may not hold up under the weight of industrial equipment.

- Noise and Vibration: Softer materials, like rubber, absorb vibrations and reduce noise, making them ideal for environments where quiet operation is important. Metal hubs, such as steel, generate more noise and vibrations, especially on hard surfaces.

- Corrosion Resistance: Materials like stainless steel are resistant to corrosion, making them ideal for wet or outdoor environments. In contrast, steel or aluminum hubs can rust unless treated with coatings, making them less suitable for corrosive conditions.

Overall, the caster wheel hub material is crucial in determining performance. It impacts durability, load capacity, noise levels, and resistance to environmental factors like corrosion. Choosing the right material ensures the caster functions efficiently and lasts as needed, especially in demanding or specialized applications.

3. What Materials Are Used for Caster Wheel Hubs?

Common materials used for caster wheel hubs include:

Steel:

- Description: Steel is one of the most commonly used materials for caster wheel hubs. It offers exceptional strength, stability, and load bearing capacity.

- Advantages: Steel hubs can support heavy weights, making them ideal for industrial and heavy-duty applications. They are cost-effective and widely available.

- Disadvantages: Steel is heavier than other materials and is susceptible to rust if not coated or maintained properly.

- Applications: Heavy-duty industrial settings, warehouses, machinery, and large equipment.

Aluminum:

- Description: Aluminum hubs are known for being lightweight, corrosion-resistant, and easy to work with.

- Advantages: Aluminum provides a high strength-to-weight ratio and is resistant to rust, making it suitable for lighter-duty applications where weight is an important consideration.

- Disadvantages: Aluminum is not as durable as steel or cast iron under heavy load conditions.

- Applications: Automotive industry, office equipment, light-duty commercial use.

Cast Iron:

- Description: Cast iron hubs are among the most durable materials available. They excel in high-load environments where strength and resistance to wear are critical.

- Advantages: High strength, excellent load-bearing capacity, and resistance to wear. Ideal for very heavy-duty applications.

- Disadvantages: Cast iron is heavier than steel and can crack under excessive impact or stress.

- Applications: Heavy industrial use, machinery, and environments with high-load requirements.

Nylon:

- Description: Nylon is a type of plastic known for its lightweight nature and low rolling resistance.

- Advantages: Corrosion-resistant, lightweight, and quiet. Offers smooth movement with reduced friction.

- Disadvantages: Not suitable for heavy-duty applications, as it lacks the strength to support very heavy loads.

- Applications: Office furniture, medical equipment, light-duty carts, and furniture.

PVC:

- Description: PVC (Polyvinyl Chloride) is another lightweight, corrosion-resistant plastic material used for caster hubs.

- Advantages: Ideal for environments exposed to moisture or chemicals, making it corrosion-resistant and economical.

- Disadvantages: Not suitable for heavy-duty or high-impact applications.

- Applications: Food processing, medical equipment, and light-duty industrial use.

Here’s a detailed breakdown of the materials commonly used in caster wheel hubs:

| Material | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Steel | High strength, durable, cost-effective | Prone to rust, heavy | Heavy-duty industrial, machinery, large equipment |

| Aluminum | Lightweight, corrosion-resistant, strong | Less durable under high load, more expensive | Light-duty commercial, automotive, office furniture |

| Cast Iron | Extremely durable, high load-bearing capacity | Heavy, brittle under impact, prone to rust | High-load industrial, machinery, heavy-duty applications |

| Nylon | Lightweight, corrosion-resistant, low rolling resistance | Not suitable for heavy-duty, limited strength | Light-duty carts, office furniture, medical equipment |

| PVC | Corrosion-resistant, lightweight, economical | Not suitable for heavy-duty, low strength | Food processing, light-duty industrial, medical equipment |

4. What Is the Best Material for a Heavy-Duty Caster Wheel Hub?

When dealing with heavy duty applications, steel and cast iron are the best choices for caster wheel hubs:

- Steel hubs are the most versatile and cost-effective option, able to handle high loads and provide good durability.

- Cast iron hubs are the strongest and most durable, making them ideal for extremely heavy-duty applications like machinery, construction, and industrial environments.

For even heavier environments where extreme stress is common, cast iron is the go-to choice, although its heavy weight and brittleness under extreme stress may limit its application in certain settings.

5. Are Metal or Plastic Caster Wheel Hubs Better?

The choice between metal and plastic hubs comes down to the specific needs of your application:

- Metal hubs (steel, cast iron) are better suited for heavy-duty, high-load, and industrial applications where strength, durability, and load-bearing capacity are essential.

- Plastic hubs (nylon, PVC) are better for lighter-duty applications that prioritize corrosion resistance, low rolling resistance, and quiet movement. These are ideal in environments like hospitals, offices, and other sensitive spaces.

Ultimately, the decision depends on whether you prioritize strength (metal) or weight and corrosion resistance (plastic).

6. What Is the Difference Between Cast Iron and Aluminum Wheel Hubs?

Cast iron hubs are significantly more durable and capable of supporting heavier loads than aluminum hubs. However, cast iron is heavier, more prone to cracking under extreme stress, and prone to rust without proper treatment.

On the other hand, aluminum hubs are lighter and corrosion-resistant, but they lack the strength required for very heavy-duty applications. Aluminum is a good choice when weight reduction is important, and the load capacity is moderate.

7. What Are the Advantages of Nylon Caster Wheel Hubs?

Nylon hubs are especially favored for applications where lightweight and low rolling resistance are critical. Some key advantages include:

- Low Rolling Resistance: Ideal for smooth surfaces, requiring less force to push.

- Corrosion Resistance: Works well in wet or chemically sensitive environments.

- Wear Resistance: Performs well in applications where friction is a concern.

However, nylon hubs should be avoided in high-load or heavy-duty applications due to their limited strength compared to metal hubs.

8. How Do I Choose the Right Caster Wheel Hub Material?

Choosing the right material for your caster wheel hub requires evaluating several key factors based on your application needs. Here’s what to consider:

- Load Capacity: If your caster needs to support heavy equipment or machinery, steel or cast iron hubs are your best bet. These materials offer high strength and load-bearing capacity, making them ideal for industrial applications. For lighter loads, aluminum can also be a good option due to its balance of strength and weight.

- Durability: For harsh environments, particularly where heavy use or exposure to tough conditions is common, steel and cast iron provide long-lasting durability. These materials resist wear and tear and are able to withstand extreme forces. However, aluminum is less durable in high-stress conditions and may not be suitable for very heavy-duty use.

- Corrosion Resistance: If your caster will be used in moist or chemically harsh environments, corrosion resistance becomes a top priority. In this case, nylon and PVC are excellent choices, as they are naturally corrosion-resistant and perform well in wet, corrosive conditions. Steel and cast iron require coatings or treatments to resist rust, which may wear off over time.

- Noise and Smoothness: For applications in noise-sensitive environments like offices, hospitals, or libraries, you’ll want to prioritize nylon and PVC hubs. These materials are quieter and provide smoother movement compared to metal hubs. If reducing noise and vibrations is essential, these options will enhance the overall user experience.

- Weight: If minimizing weight is critical, consider aluminum or nylon hubs. These materials are much lighter than steel and cast iron, making them ideal for applications where ease of maneuverability and portability are important, such as in office furniture or light-duty carts.

By evaluating these factors—load capacity, durability, corrosion resistance, noise levels, and weight—you can select the caster wheel hub material that best suits your specific requirements, ensuring optimal performance and longevity.

9. Frequently Asked Questions (FAQs)

Q1: How often should I replace my caster wheel hubs?

The lifespan of a caster wheel hub depends on the material, usage, and environment. Metal hubs like steel and cast iron typically last longer, potentially 5-10 years in industrial settings. Plastic hubs like nylon or PVC may need replacement every 1-3 years, especially under heavy use or in challenging environments.

Q2: Are there any special maintenance requirements for different hub materials?

Yes, maintenance varies by material:

Steel and cast iron hubs require periodic rust prevention and may need protective coatings

Aluminum hubs need minimal maintenance but should be checked for oxidation

Nylon and PVC hubs should be cleaned regularly and inspected for wear or chemical degradation

Always lubricate bearings and check for smooth rotation regardless of hub material

Q3: What temperature ranges can different wheel hub materials withstand?

Steel and cast iron: -40°F to 500°F (-40°C to 260°C)

Aluminum: -20°F to 300°F (-29°C to 149°C)

Nylon: -40°F to 250°F (-40°C to 121°C)

PVC: 32°F to 180°F (0°C to 82°C)

Always confirm specific temperature tolerances with the manufacturer for your exact application.

Q4: How do I know if I’m overloading my caster wheel hub?

Signs of overloading include:

Visible deformation or bending of the hub

Increased friction or difficulty rotating

Unusual noises during movement

Reduced mobility or increased resistance

Visible wear or stress marks on the hub

Always choose a hub material with a load capacity that exceeds your expected weight requirements by at least 30-50% for safety.

10. Summary

When choosing a caster wheel hub, you have to consider a few factors: load capacity, environmental conditions, and the noise level required. If you’re going to be doing heavy duty stuff, you want a steel or cast iron hub. If you’re going to be doing lighter stuff and you want it to be quiet, you want a nylon or PVC hub. You need to know the properties of each material so you can pick the right caster for your application.

For more questions or needs, reach us at:

Email: info@techincastor.com

Tel/WhatsApp: +86 13417057114