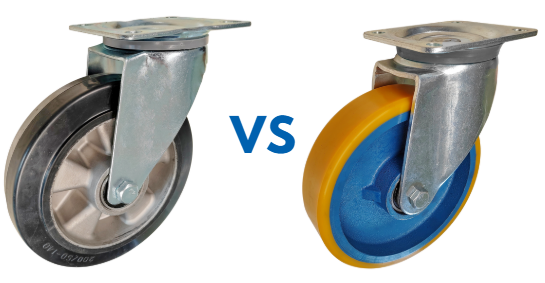

When you’re choosing caster wheels for industrial, commercial, and logistics applications, you’ll often have to choose between elastic rubber and polyurethane (PU). Both are tough and versatile, but they have different properties that can affect how your equipment performs.

In this article, we’ll look at the differences between elastic rubber and PU caster wheels. This will help you decide which one is best for your needs.

1. What Are Elastic Rubber Caster Wheels and What Makes Them Beneficial?

Elastic rubber caster wheels, unlike regular rubber, are crafted from a specific elastomer that offers superior flexibility and shock absorption. This type of material provides an ideal solution for environments where smooth, quiet, and protective movement is required.

Key Features and Benefits of Elastic Rubber Caster Wheels:

- High Load Capacity: Despite their flexibility, elastic rubber wheels offer a high load-bearing capacity of up to 450 kg per wheel, which is suitable for medium-duty applications.

- Enhanced Shock Absorption: The elasticity of these wheels makes them ideal for absorbing shocks, vibrations, and impacts, ensuring a smoother, quieter operation on rough and uneven surfaces.

- Floor Protection: Their softness helps prevent floor damage, making them suitable for sensitive environments such as healthcare facilities, retail spaces, and warehouses with delicate flooring.

- Durability: Elastic rubber wheels are highly abrasion resistant, ensuring a long service life even with frequent use on rough surfaces.

Elastic rubber caster wheels are particularly suited for environments where comfort and quiet operation are crucial, such as in logistics, trade, or in settings with sensitive floors.

2. What Are Polyurethane Caster Wheels? Features & Benefits

Polyurethane (PU) caster wheels are made by coating a polyurethane layer around a metal or plastic core. PU is a synthetic material that combines the best aspects of both rubber and plastic, offering excellent performance in various industrial settings.

Key features and benefits of polyurethane caster wheels include:

- Superior Durability: PU wheels are highly durable and resistant to abrasion, cuts, and tears. They can withstand heavy loads and rough surfaces, making them ideal for industrial environments that involve frequent or high-traffic movement.

- Extreme High Load Capacity: PU caster wheels can bear heavy loads up to 1000 kg per wheel, making them perfect for forklifts, warehouse trolleys, and material handling equipment where high strength is required.

- Abrasion and Chemical Resistance: Polyurethane is resistant to oils, greases, and various chemicals, which enhances the wheel’s durability and performance in harsh conditions.

- Smooth Movement: Even on rough or uneven surfaces, PU wheels provide a smooth and stable ride, unlike rubber wheels, which can degrade faster in these conditions.

- Better Environmental Resistance: Polyurethane performs exceptionally well under extreme temperatures and is resistant to UV rays, making it more suitable for outdoor applications than rubber wheels.

3. How Do Elastic Rubber and PU Wheels Perform in Different Industrial Settings?

Both elastic rubber and PU caster wheels offer great versatility, but their performance varies depending on the environment.

Indoor Settings

- Elastic Rubber: Best for quiet environments like retail stores and hospitals, offering smooth, noise-free operation and floor protection.

- PU: Great for hard floors in warehouses and manufacturing plants, providing durability and resistance to oils and scuffs.

Outdoor and Rough Surfaces

- Elastic Rubber: Works well on uneven surfaces, providing shock absorption and smooth movement on paved pathways or factory yards.

- PU: Handles rougher outdoor surfaces like gravel and asphalt, with high durability and load-bearing capacity.

Harsh Environments

- Elastic Rubber: Suitable for light industrial settings with minimal chemical exposure.

- PU: Ideal for chemical plants and automotive factories, offering high resistance to chemicals, oils, and abrasion.

Heavy Duty Applications

- Elastic Rubber: Supports loads up to 450 kg, perfect for logistics and light manufacturing.

- PU: Handles heavy-duty loads of up to 1000 kg, ideal for warehouses and large machinery.

4. Elastic Rubber vs. Polyurethane Caster Wheels: Key Differences

| Property | Elastic Rubber | Polyurethane |

|---|---|---|

| Load Capacity | Up to 450 kg per wheel, ideal for medium duty applications. | Up to 1000 kg per wheel, perfect for heavy duty environments. |

| Shock Absorption | Excellent shock absorption, great for rough or uneven surfaces. | Moderate shock absorption, more suited for heavy load support. |

| Abrasion Resistance | Good abrasion resistance but wears faster than PU. | Very high abrasion resistance, longer lifespan in tough environments. |

| Noise Level | Very low noise, perfect for quiet areas like retail. | Moderate noise, louder than elastic rubber but still acceptable. |

| Floor Protection | High protection for sensitive floors. | Moderate protection, better for hard floors. |

| Chemical Resistance | Low resistance to chemicals. | High resistance, ideal for environments with oils and solvents. |

Elastic rubber wheels are ideal for environments requiring shock absorption, low noise, and floor protection, making them perfect for retail and light manufacturing. Polyurethane wheels, on the other hand, are suited for heavy duty applications, offering better abrasion resistance and chemical resistance, making them the go-to for industrial settings.

5. Cost Comparison: Elastic Rubber vs. Polyurethane Caster Wheels

When deciding between elastic rubber and polyurethane caster wheels, cost is an important factor to consider. The price difference typically reflects the material properties, load capacity, and durability of the wheels.

Elastic Rubber Caster Wheels:

- Lower Initial Cost: Elastic rubber wheels are generally more affordable upfront compared to polyurethane wheels.

- Long Term Savings: While their lifespan may be shorter, they offer cost-effectiveness for light to medium-duty applications where budget constraints are a consideration.

Polyurethane Caster Wheels:

- Higher Initial Cost: Polyurethane wheels are more expensive than elastic rubber due to their superior durability, higher load capacity, and enhanced chemical resistance.

- Better Investment for Heavy Duty Applications: Despite the higher initial price, polyurethane wheels can save costs in the long term. Their longer lifespan, reduced maintenance needs, and higher performance under heavy loads make them a more economical choice for industrial environments.

6. Use Cases: When to Opt for Elastic Rubber Caster Wheels vs. Polyurethane Wheels

Elastic Rubber Caster Wheels: Ideal for Flexibility, Shock Absorption, and Noise Reduction

- Retail and Commercial Spaces: Provide smooth, quiet movement, making them ideal for areas where noise control and customer comfort are important.

- Hospitals and Healthcare: Their shock absorption and quiet operation make them perfect for sensitive environments where mobility is essential without disturbing patients or staff.

- Medium to Heavy Industrial Applications: Excellent for moving heavy loads on uneven or rough surfaces, offering high flexibility and floor protection, ideal for medium to heavy-duty material handling in factories and logistics.

Polyurethane Caster Wheels: Best for Strength, Durability, and High Load-Bearing Capacity

- Warehouses and Manufacturing Plants: Perfect for moving heavy machinery, equipment, and materials with high load-bearing capacity and durability.

- Shipping and Logistics: Well-suited for environments with exposure to chemicals, oils, or rough surfaces, providing resistance and longevity under heavy use.

- Heavy Duty Industrial Equipment: Ideal for large-scale machinery and automated systems where strength, resilience, and high load-bearing capacity are essential.

7. Maintenance Tips for Elastic Rubber and Polyurethane Caster Wheels

Both elastic rubber and polyurethane caster wheels are designed for low maintenance, but a few care practices can help ensure they perform optimally and last longer:

Elastic Rubber Caster Wheels:

- Regular Cleaning: Clean the wheels to prevent the buildup of dirt and debris, which can affect their performance.

- Temperature Care: Avoid exposing the wheels to extreme temperatures above +80°C or below -20°C to preserve their elasticity and shock-absorbing properties.

- Surface Consideration: Use the wheels on suitable surfaces to maintain their shock-absorption capabilities and protect against wear.

Polyurethane Caster Wheels:

- Wear Check: Regularly inspect the wheels for signs of wear and replace them when necessary to avoid performance decline.

- Keep Clean: Ensure the wheels remain free from oils, grease, or chemicals that could compromise their grip and cause slippage.

- Inspect for Damage: Check for cracks or deformities, particularly when carrying heavy loads, to maintain structural integrity and safe operation.

8. Frequently Asked Questions (FAQs)

Q1: Are polyurethane casters better than elastic rubber?

Answer: Not exactly, it depends on the application. PU casters are stronger and better suited for heavy duty tasks, while elastic rubber casters are ideal for noise sensitive, floor protecting, and shock absorbing needs.

Q2: What is the best material for heavy duty casters?

Answer: Polyurethane is typically the best choice for heavy duty applications due to its high load-bearing capacity (up to 1000 kg per wheel) and resistance to chemicals.

Q3: Can elastic rubber caster wheels be used outdoors?

Answer: Yes, elastic rubber wheels are versatile and can be used outdoors, but their performance may decrease in extreme temperatures.

Q4: Do PU caster wheels work on rough surfaces?

Answer: Yes, but they may not perform as well as elastic rubber wheels on very rough or uneven surfaces.

Q5: How long do elastic rubber caster wheels last?

They typically last longer than regular rubber but shorter than polyurethane, depending on the load and usage conditions.

9. Summary

Whether you choose elastic rubber or polyurethane caster wheels depends on what you need. Elastic rubber offers superior comfort, noise reduction, and shock absorption, making it ideal for sensitive environments. On the other hand, polyurethane excels in heavy duty industrial applications, offering higher load capacities and greater durability. By knowing what each material is good at, you can make sure your casters do what you want them to do.

For more questions or needs, reach us at:

Email: info@techincastor.com

Tel/WhatsApp: +86 13417057114