Choosing the right caster wheel bearing is critical to the longevity, smooth operation, and efficiency of your equipment. For buyers, understanding the differences between the various types of caster bearings can make a big difference in the performance and durability of their equipment.

Let’s take a look at the three most commonly used caster wheel bearings: Plain Bearing, Roller Bearing, and Ball Bearing.

Plain Bearing

Plain bearings are the simplest and most cost-effective type of bearing. Plain bearings consist of a single, smooth surface that comes into direct contact with the wheel hub. This design offers several advantages:

- Cost-Effectiveness: Plain bearings are often the most affordable option, making them suitable for applications with budget constraints.

- Simplicity: With no moving parts, plain bearings are less prone to mechanical failure.

- Lightweight: Their simple design ensures a lightweight build, ideal for applications where weight is a consideration.

However, the simplicity of plain bearings comes with some trade-offs:

- Friction and Wear: Since there is no rolling element, plain bearings have higher friction than roller or ball bearings, which can lead to quicker wear, especially under heavy loads.

- Load Capacity: They are best suited for light to moderate loads and may not perform well in heavy-duty applications.

- Maintenance: Due to higher friction, plain bearings may require regular lubrication to maintain smooth operation and reduce wear.

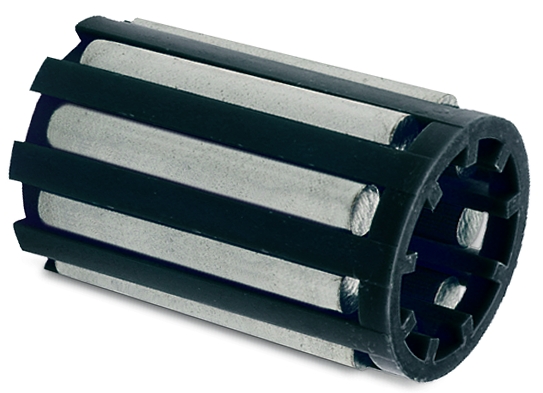

Roller Bearing

Roller bearings are designed with cylindrical rollers, which distribute the load over a larger surface area. Roller bearings offer several benefits:

- Durability: The increased contact area between the rollers and the raceway allows roller bearings to handle higher loads with less wear and tear, making them ideal for industrial and heavy-duty applications.

- Lower Friction: Compared to plain bearings, roller bearings have lower friction, allowing for smoother movement, especially under heavy loads.

- Versatility: Roller bearings are versatile and can be used in a wide range of applications, from machinery to industrial carts.

Despite these advantages, roller bearings also have some limitations:

- Size: Roller bearings are generally larger and heavier than ball bearings, which may not be suitable for compact or lightweight designs.

- Cost: They are typically more expensive than plain bearings, though this is offset by their durability and load-handling capabilities.

- Maintenance: While they require less maintenance than plain bearings, roller bearings still benefit from occasional lubrication to prolong their lifespan.

Ball Bearing

Ball bearings are one of the most commonly used types of caster wheel bearings. They use small, hardened steel balls that roll within a race, significantly reducing friction. Ball bearings are known for:

- Low Friction: The rolling motion of the balls within the raceway results in minimal friction, making ball bearings suitable for applications requiring smooth, high-speed movement.

- Precision: Ball bearings provide precise movement, which is critical in applications where accuracy is important.

- Sealed Design: Most ball bearings are sealed, protecting them from dirt, dust, and debris, thereby reducing the need for frequent maintenance.

However, ball bearings have some considerations:

- Load Capacity: While excellent for high-speed applications, ball bearings are not as robust as roller bearings when it comes to handling heavy loads.

- Cost: Ball bearings are more expensive than plain bearings but offer a balance between cost and performance for many applications.

- Maintenance: Although they are sealed, ensuring they remain free of debris and properly lubricated can help extend their operational life.

People Also Ask

1. What is the Most Common Type of Wheel Bearing?

The most common type of wheel bearing is the ball bearing. Ball bearings are popular due to their versatility, offering a balance between low friction and durability. They are sealed to prevent contamination from dirt and debris, making them suitable for various applications, from light-duty carts to precision instruments. Their ability to support both radial and axial loads while providing smooth operation makes them a go-to choice for many buyers.

2. How Do Roller Bearings Compare to Ball Bearings in Terms of Durability?

Roller bearings are generally more durable than ball bearings in terms of load-handling capacity. The cylindrical rollers provide a larger contact area, distributing the load more evenly across the bearing surface. This design allows roller bearings to withstand greater stress without deformation, making them ideal for heavy-duty applications. However, ball bearings excel in high-speed scenarios and applications requiring low friction. While roller bearings are superior in terms of load capacity and durability, ball bearings are better suited for applications where speed and smoothness are prioritized.

3. What are the Maintenance Requirements for Plain Bearings?

Plain bearings require regular maintenance to ensure smooth operation and longevity. Key maintenance tasks include:

- Lubrication: Since plain bearings have higher friction, they need periodic lubrication to minimize wear and tear. Using the right type of lubricant is crucial for optimal performance.

- Cleaning: Because plain bearings are not sealed, they are more susceptible to dirt and debris. Regular cleaning is necessary to prevent contaminants from causing increased friction or wear.

- Inspection: Regularly inspect plain bearings for signs of wear, such as scoring or pitting on the surface. Early detection can prevent further damage and prolong the bearing’s lifespan.

Proper maintenance can extend the life of plain bearings, making them a cost-effective option in the long run.

4. How to Choose the Right Caster Bearings?

When selecting the right caster bearings, consider the following factors:

- Load Capacity: Assess the maximum weight the caster will need to support. For heavy loads, roller bearings are typically more suitable, while ball bearings are ideal for moderate loads with a need for smooth operation.

- Speed Requirements: If the application requires high-speed movement, ball bearings are preferred due to their low friction.

- Environmental Conditions: Consider the environment where the casters will be used. In dirty or corrosive environments, sealed ball bearings are recommended to prevent contamination and rust.

- Budget: While plain bearings are the most affordable, they require more maintenance. Roller and ball bearings offer better performance and durability but at a higher cost.

By evaluating the specific needs of the application, buyers can select the most appropriate caster bearing type to ensure optimal performance and longevity.

5. How to Replace the Bearing?

Replacing a caster wheel bearing is a straightforward process:

- Remove the Wheel: Detach the caster wheel from the frame by unscrewing the bolt or fastener.

- Extract the Old Bearing: Use a bearing puller or a similar tool to carefully remove the old bearing from the wheel hub.

- Clean the Hub: Before installing the new bearing, clean the wheel hub to remove any dirt, debris, or old lubricant.

- Insert the New Bearing: Press the new bearing into the hub, ensuring it fits snugly. For roller and ball bearings, ensure they are properly sealed to prevent contamination.

- Reattach the Wheel: Secure the wheel back onto the caster frame and tighten the bolt or fastener.

Regularly replacing worn-out bearings can enhance the performance and lifespan of caster wheels, ensuring smooth and efficient operation.

Summary

Choosing the right caster wheel bearing is critical to the efficiency, durability, and smooth operation of your equipment. Whether you choose a plain bearing for cost-effectiveness, a roller bearing for heavy-duty load handling, or a ball bearing for precision and speed, understanding the strengths and maintenance requirements of each type is key. Make an informed choice to keep your equipment running efficiently and effectively for the long term.